Apparel

Supporting the footwear and apparel industry in quickly adapting to business fluctuations and market demands.

ROI period: 1.5 years

Transportation efficiency improvement: 70%

AMR Quantity: 8

Application Link

√ Shoe material transfer

Case Introduction

Worldwide supplier of top of the line sporting apparel

Customer Demand

Need to introduce automatic transportation equipment to replace workers to carry out long-distance multi-floor transportation;

Improve transportation efficiency。

Project Features

It is difficult to deploy in older factories where the elevators and passageways are quite narrow.

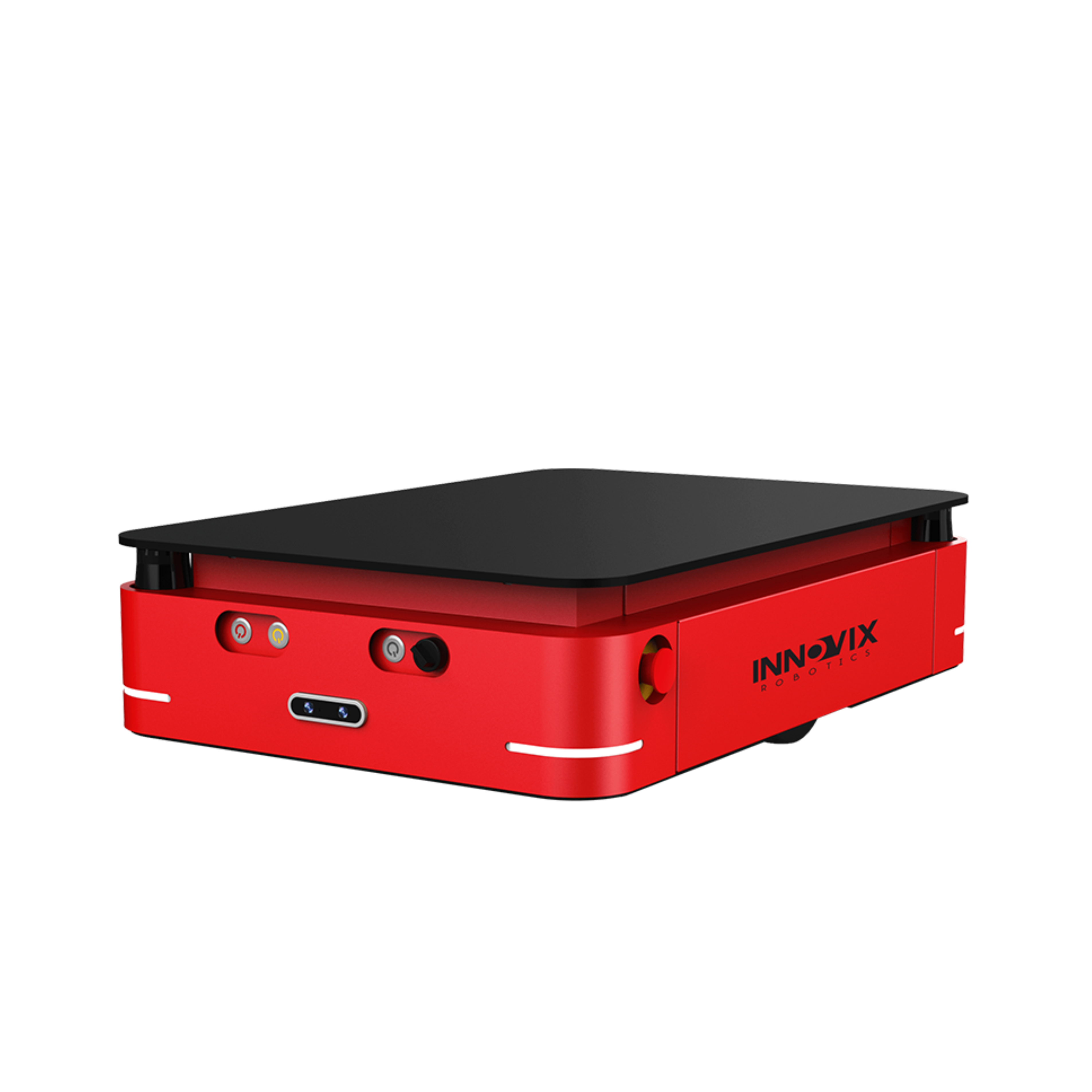

Solutions

Personalized scheduling of pager improves handling efficiency, and the distributed scheduling system connects to the elevator IoT to realize multi- floor transportation.

Hardware: Customized lifting AMR + Customized material rack + Charging Station + Call box;

Software: Cluster scheduling system platform +material management platform+ customized mobile interactive software.

Added Value

Labor cost reduction by replacing what would have been 18 positions with AMRs;

The transportation efficiency has been significantly improved.