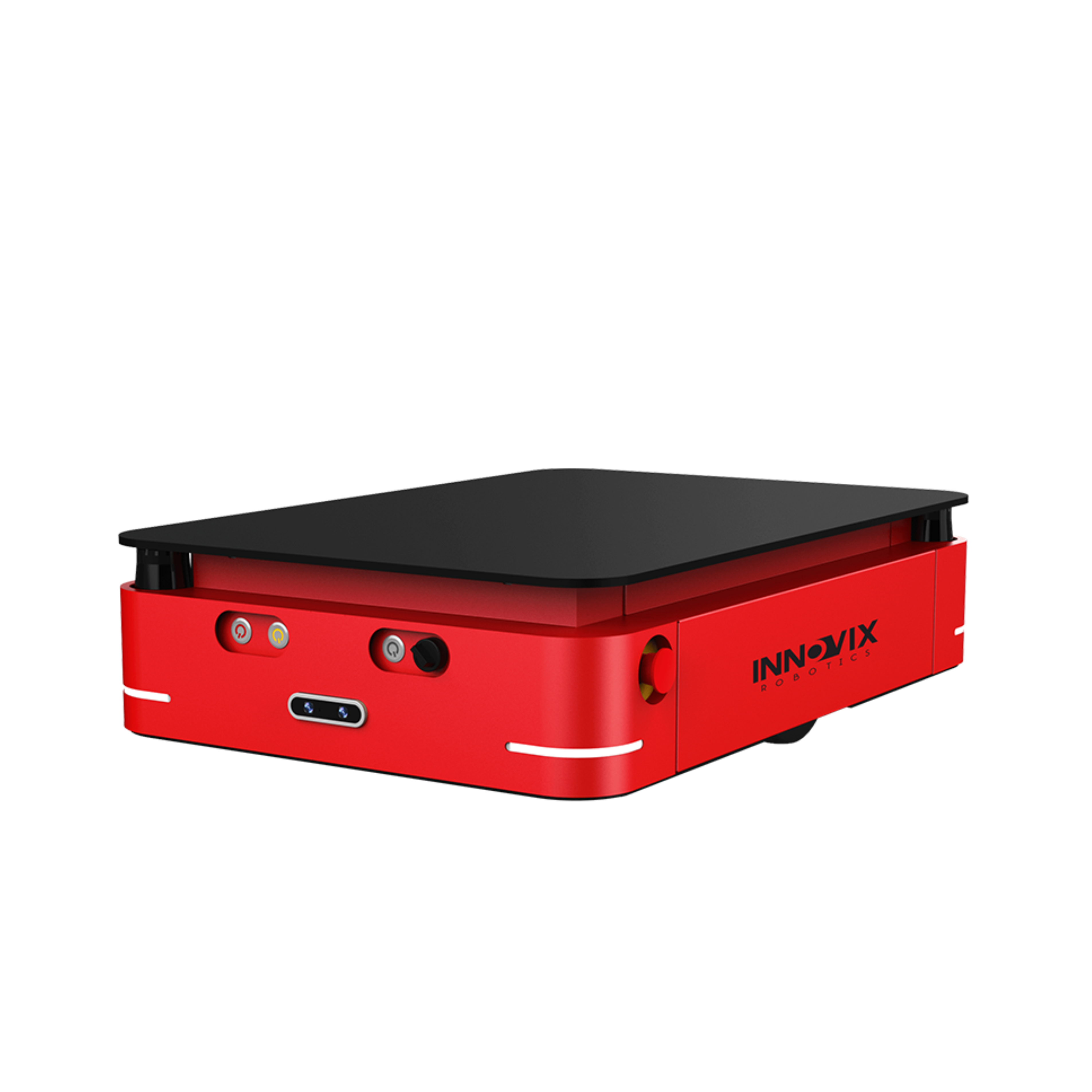

Auto Parts

Connecting material handling between stamping, welding, painting, and final assembly stages

ROI period: 2 years

Efficiency improvement: 40%

AMR Quantity: 12

Application Link

√ Launch the seat frame material preparation online

Case Introduction

Large Chinese auto parts manufacturer

Customer Appeal

Seeking the implementation of automated transportation equipment to alleviate workload and reduce labor costs.

Project Characteristics

① Multilevel transportation required between three floors for travel from the production line to the warehouse;

② The factory relies on a significant number of specialized skip cars that cannot be modified。

Solutions

A customized AMR seamlessly fits into the original scenario without modification, aided by a distributed scheduling system for multi-level cross-floor transportation.

Hardware: Customized lifting AMR, charging station, automatic lifting platform.

Software: Distributed cluster management

Impact Value

Significantly enhances transportation efficiency and substantially reduces labor intensity;

Replaces the need for transportation roles previously filled by 15 individuals, reallocating manpower to higher-value tasks。