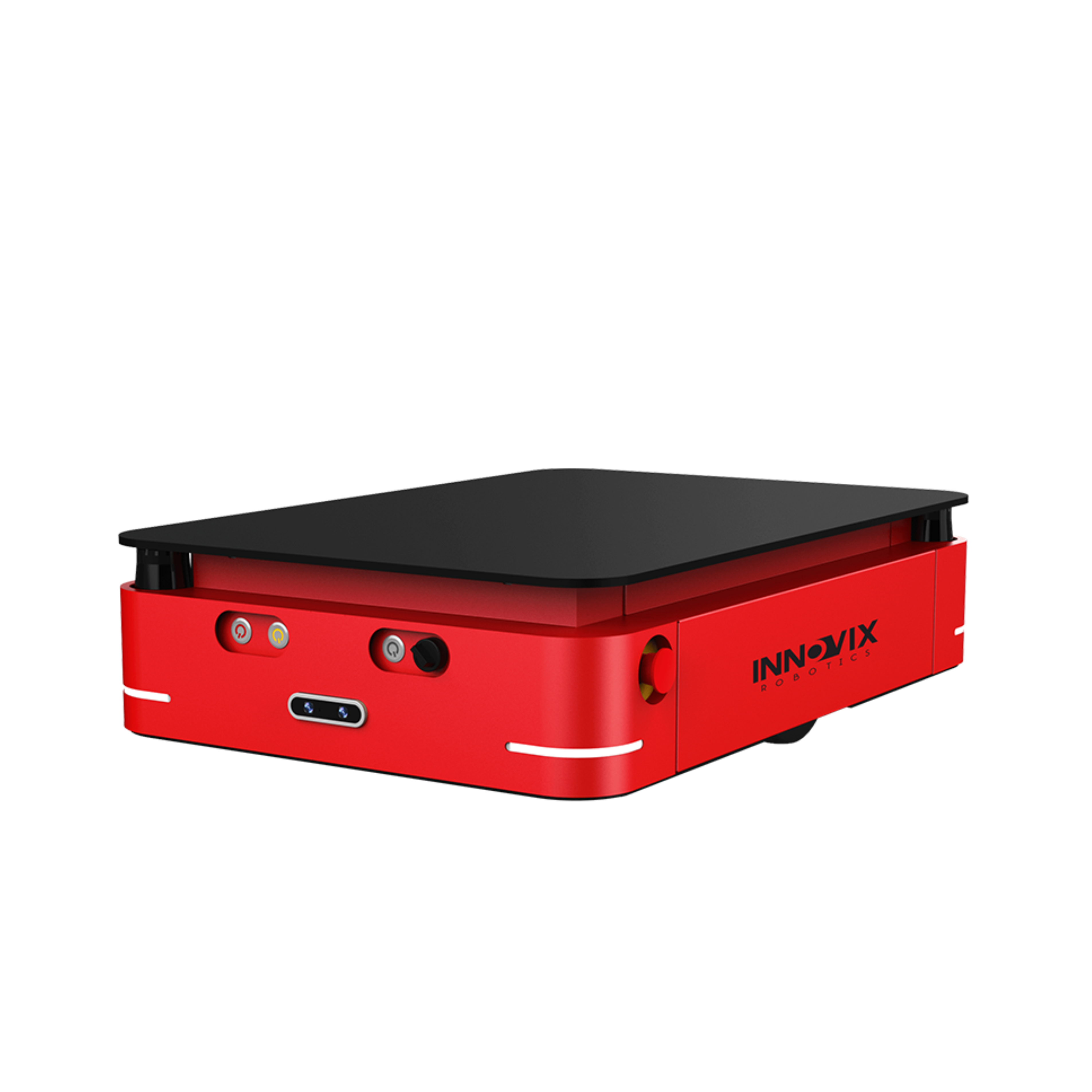

Third Party Logistics

Efficient and agile logistics services, "0 error" in and out of the warehouse for large quantities of goods.

ROI period: 2 years

Quantity of Picking and Whole Pallet Handling AMR: 10

Labor efficiency improvement: 50%

Application Link

√ Finished products go offline √ Order Picking

Project Features

√ The production links are diverse and there are many circulation stations;

√ There are many business processes, and the application and scheduling logic of AMR are complex.

Case Introduction

A Chinese Leading Third Party Logistics Company

Customer Demand

Want to introduce automation equipment to improve the existing operation process and match the operation characteristics through peak seasons;

Would like to establish a digital management and control system of logistics information.

Solutions

AMR replaces manual labor to complete long-distance transportation of materials, and the distributed scheduling system realizes ensures order operation.

Hardware:Customized picking AMR with interactive lever and customized cart accessories.

Software:Distributed cluster management system + material management platform + customized vehicle interactive software.

Added Value

Human efficiency increased by 50%;

Enables the whole system to connect with the WMS system of the warehouse, and the warehouse realizes the whole-process by digital management and control.