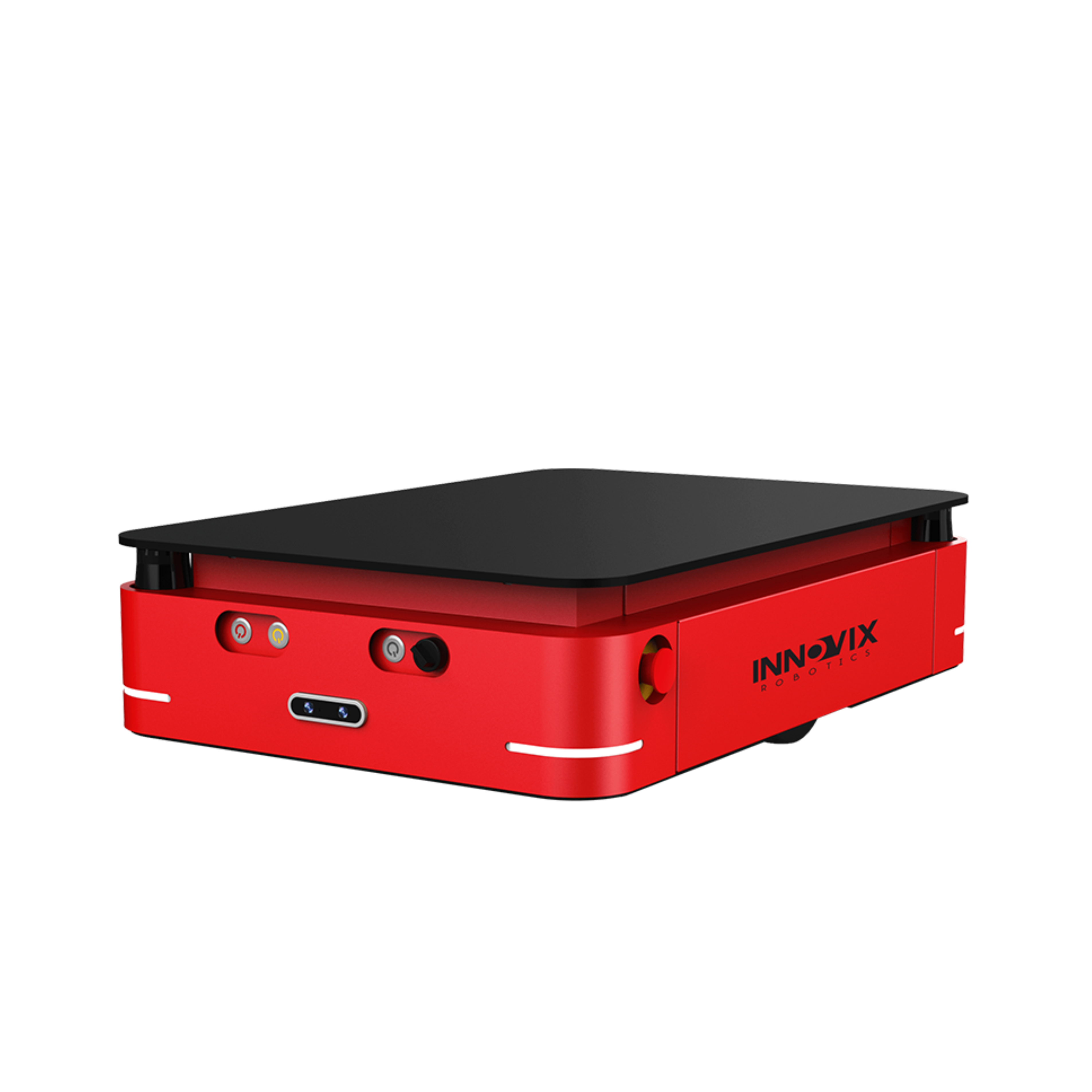

New Energy

Empowering the new energy, photovoltaic, and lithium battery industries to achieve advanced manufacturing.

ROI period: 1.5 years ,

AMR Quantity: 6 units

Work flow

√ raw material feeding to the production line

√ QC

√ finished products off the production line

Case Introduction

Leading Chinese lithium-ion power battery manufacturers

Customer Demand

Upgrade automation levels and enhance productivity in the new factory by replacing the AGV solution with an AMR solution.

Project Features

① Diverse production processes with multiple circulation stations;

② Complex workflow necessitating intricate AMR deployment and scheduling logic。

Solutions

Enhance customized components to accommodate a range of scenarios, while the distributed scheduling management system addresses scheduling challenges.

Hardware: Customized integrated transmission components, AMR + charging station + call box.

Software: Distributed cluster management system, material management platform.

Impact Value

Substitute the original AGV solution, reducing the expense of large-scale magnetic stripe deployment, and replacing electric forklifts in certain scenarios.