Cosmetics

Continuously delivering multiple high-quality overseas projects in the cosmetics industry.

ROI period: 2 years

Quantity of Automatic Loading and Unloading AMR: 6

Quantity of AMR for Whole Pallet Handling: 30

International Standard: CE Certification

Application Link

√ Launch raw materials online √ Finished products go offline √ Packaging materials go online

Case Introduction

One of the largest cosmetic companies in the world

Customer Demand

① Automated transportation equipment is needed for labor cost reduction;

② Want to improve production capacity and production efficiency;

③ Need to ensure that international safety standards and safe production protocols are met.

Project Features

① The floor plan of the factory is very tight and the passing space is narrow. Some sections have tortuous narrow passages, and most passages are occupied by forklifts. There is also a need for the auto door synchronization;

②Need to ensure the production rate efficiency and accuracy.

Solutions

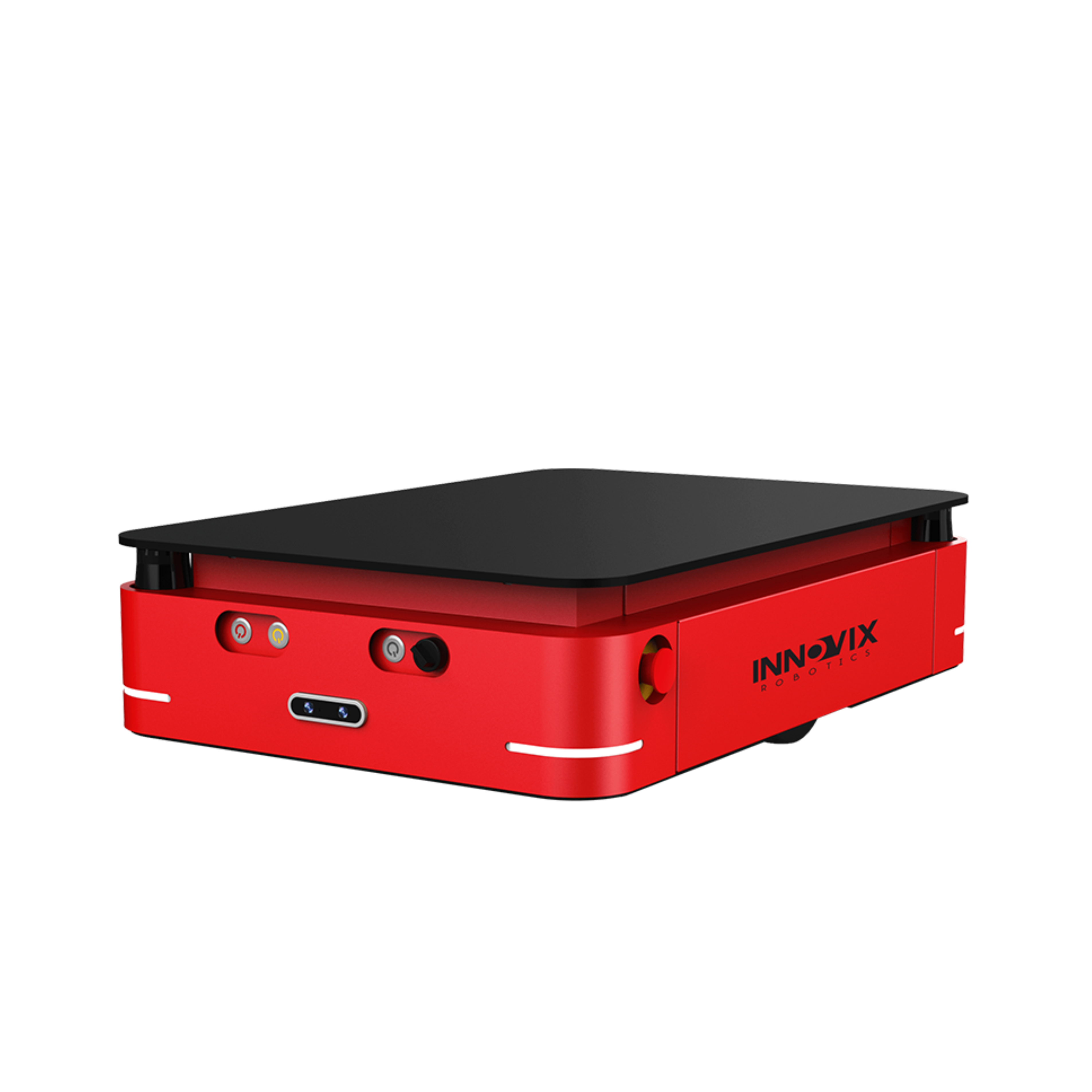

CE certified AMR provides whole pallet handling + automatic material transfer, and the distributed scheduling system ensures efficient operation.

Hardware: Customized double-layer roller AMR + 1200kg load AMR with lifting assembly + charging station+material platform;

Software: Distributed cluster management system + material management platform + customized mobile interactive software。

Added Value

① Greatly reduces labor costs;

② The production efficiency has been significantly improved;

③ Significantly reduces the need for forklift operators.