At present, the rapid development of artificial intelligence, ChatGPT, as the top model in the field of AIGC, is expected to accelerate the penetration of AI in various industries and disrupt existing forms of productivity.

"Manufacturing is an important battlefield for AI big models," Zhang said. "The biggest opportunity in the next 10 years is the integration of cloud, AI and machines in the physical world. Robots fetching water is just the first step.

Robots are the core carrier integrating advanced manufacturing, big data and artificial intelligence. At present, the robot industry is in an era of transformation and upgrading, and the traditional machines and equipment in the past have begun to change into new equipment with more human intelligence, wisdom and flexibility. There are three driving forces for the long-term development of the industry: first, the "thrust" of the transformation and upgrading of the manufacturing industry; Second, high labor costs force the "pull" of machine replacement; The third is the "catalytic power" of policy support.

Artificial intelligence is changing all walks of life, and the logistics industry is one of them. With the blessing of artificial intelligence, the logistics system can imitate human intelligence, have the ability of thinking, perception, learning and reasoning judgment, and can solve some problems in logistics by itself. At the application level, artificial intelligence mainly promotes the cost reduction and efficiency of the logistics industry by enabling the four major links of "transportation, warehousing, distribution, and customer service".

In the process of warehouse upgrading, artificial intelligence can get the optimal solution of warehouse upgrading by establishing a system based on big data, and only need to input the relevant demand parameters.

In terms of unmanned warehouse operation, thanks to artificial intelligence technologies such as machine vision and evolutionary algorithms, various types of logistics robots perform their respective roles, responsible for handling, sorting, stacking and other work. After a period of time, the robot can also achieve self-sensing, self-decision-making and self-execution for logistics operations in the warehouse, achieving a higher degree of automation.

In the traditional logistics industry, manual operation is inevitable. However, manual operation has many drawbacks, such as low efficiency, easy to make mistakes and so on. The emergence of intelligent robots can effectively solve these problems. Robots can work without interruption, without fatigue and errors, thus improving the efficiency of the logistics industry.

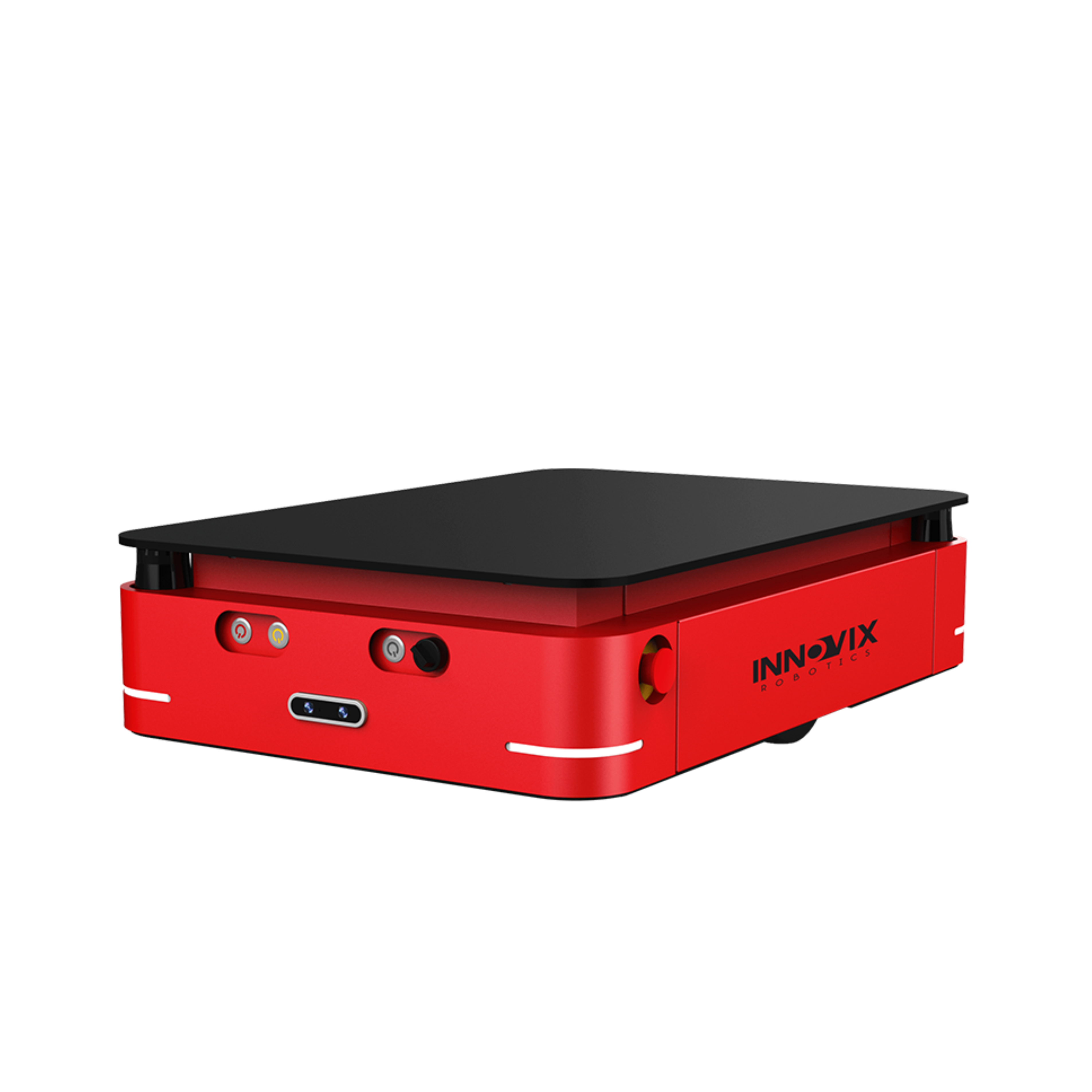

Today's AMR robots are widely used in the logistics industry, such as the AMR robot can achieve unmanned driving, autonomous navigation, automatic obstacle avoidance, multi-machine scheduling, automatic traffic control and other functions. The AMR robot can achieve 24-hour high-speed repetitive operation, and the working beat is much higher than that of the manual, so it can greatly improve the work efficiency, but also reduce the labor cost and management cost, and improve the storage efficiency. In the logistics distribution, the stable stone robot can automatically complete the sorting, packaging and distribution of goods. These tasks are difficult to complete with traditional manual operation, but the stable stone AMR robot can easily complete them.

The AMR robot can also be seamlessly connected with all kinds of automation equipment, such as automatic shelving, automatic sorting, automatic loading and unloading, etc., to realize the whole process automation of warehousing and logistics. It can conduct real-time monitoring and analysis through the cloud data platform, can view the robot's operating status, task execution, logistics efficiency and other data, provide customers with intelligent logistics management services, and can also optimize and upgrade according to data feedback.

In addition to improving efficiency, intelligent mobile AMR robots like this one can also bring more business opportunities to logistics companies. With the continuous development of robot technology, the application range of robots is also expanding. In the future, robots will play a more important role in the logistics industry, bringing more business opportunities for logistics enterprises.

Driven by artificial intelligence, new technologies such as automatic cargo sorting systems and intelligent distribution robots will continue to trigger a new round of intelligent changes in the logistics industry, promote changes in the industrial structure, and bring new opportunities for the development of the logistics industry. McKinsey estimates that by introducing AI into their processes, logistics companies will generate $1.3-2 trillion in economic value annually. The application of robots not only improves the efficiency of the logistics industry, but also brings more business opportunities for logistics enterprises. In the era of artificial intelligence, robots will lead the logistics industry to open the efficiency "storm" mode, and bring a better future for the logistics industry.

As a pioneer of AMR laser, vision integrated navigation and distributed cluster scheduling algorithms, Weishen Robot provides AMR robot products and comprehensive flexible logistics solutions based on laser and vision integrated navigation for logistics scenarios in various vertical industries, creating stable and efficient productivity and promoting users' flexible upgrade of intelligent logistics.