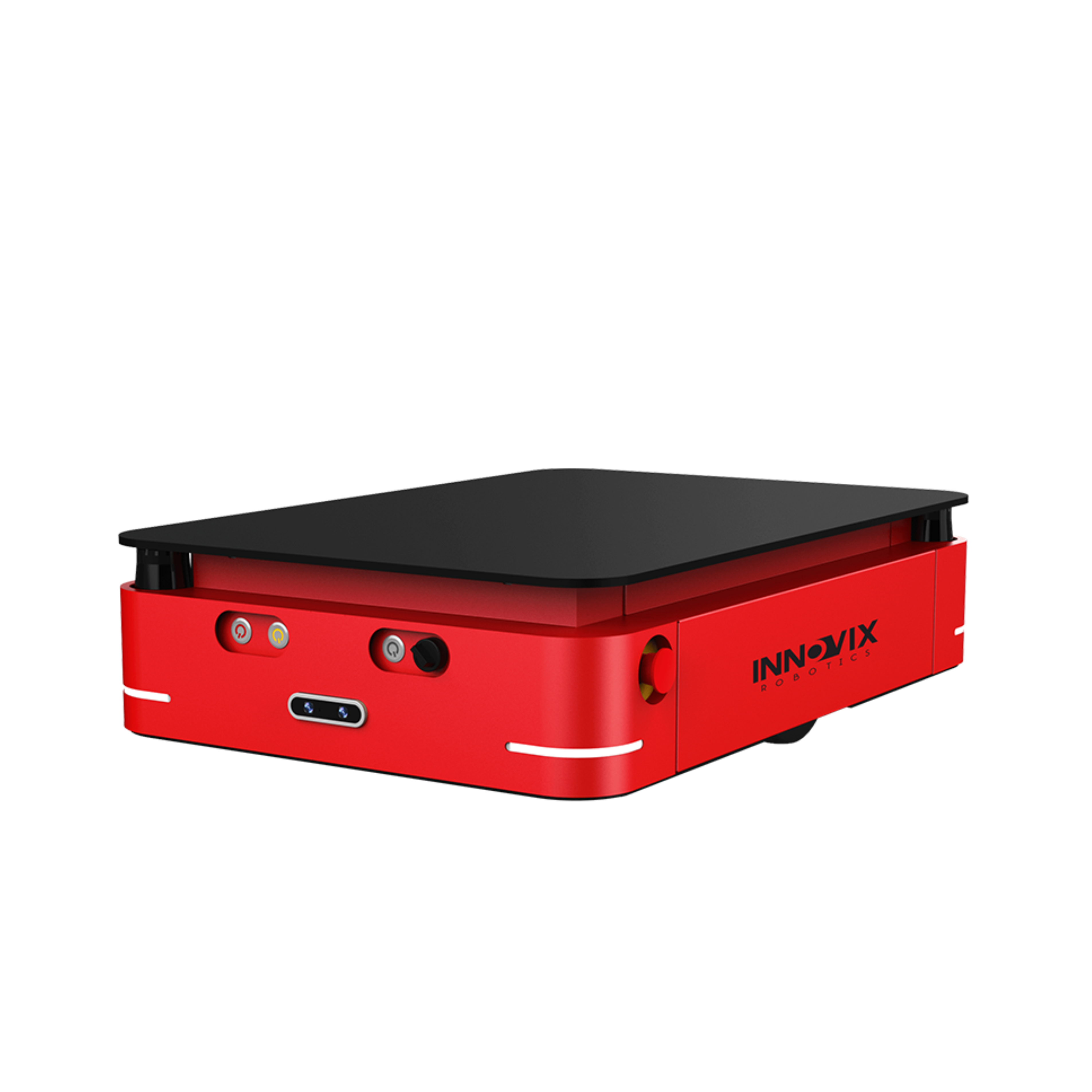

Recently, Stable stone Robot announced that the "fifth generation multi-modal flexible AMR" full series of new products will be released on October 31, 2023! This will be a revolutionary innovation and subversive change in the history of mobile robot development. It means that after the magnetic permeability AGV, two-dimensional code AGV, laser AGV, and visual autonomous mobile robot, the fifth generation mobile robot officially stepped on the stage!

Recently, Stable stone Robot announced that the "fifth generation multi-modal flexible AMR" full series of new products will be released on October 31, 2023! This will be a revolutionary innovation and subversive change in the history of mobile robot development. It means that after the magnetic permeability AGV, two-dimensional code AGV, laser AGV, and visual autonomous mobile robot, the fifth generation mobile robot officially stepped on the stage!

[Pushing boundaries, mobile robots need to be more 'smart']

1、 What is the "fifth generation"?

The first three generations of mobile robots are mainly divided according to the different navigation methods of AGVs.

The first generation of magnetic stripe navigation is mainly to lay magnetic stripes on the ground to achieve vehicle control and navigation by measuring the magnetic field signal on the path. This way the route is not easy to change, the flexibility of handling is not enough;

The second generation of two-dimensional code navigation obtains the current location information by analyzing the two-dimensional code information. This way the path needs regular maintenance, if the site is complex, you need to frequently replace the two-dimensional code, the precision and service life of the gyroscope are strict requirements;

The third generation of laser navigation has high manufacturing costs and relatively high environmental requirements (external light, ground requirements, visibility requirements, etc.);

The fourth-generation AMR has added machine vision, environmental recognition and other technologies, and can independently plan logistics routes according to algorithms, with a low level of perception and limited environmental adaptability.

The fifth-generation multi-modal flexible AMR robot, through the upgrading of the GPU computing power of the peer device and the introduction of the computing cluster cloud server, combined with high-performance real-time deep learning AI, automatic driving technology and ChatGPT large model network, subverted the capability definition of traditional industrial mobile robots. It realizes more robust environmental cognition, dynamic feedback, task reasoning, intelligent decision-making, broadens the scenario and business scope, and increases the manual replacement rate to 85%.

2、What is "multimodal"?

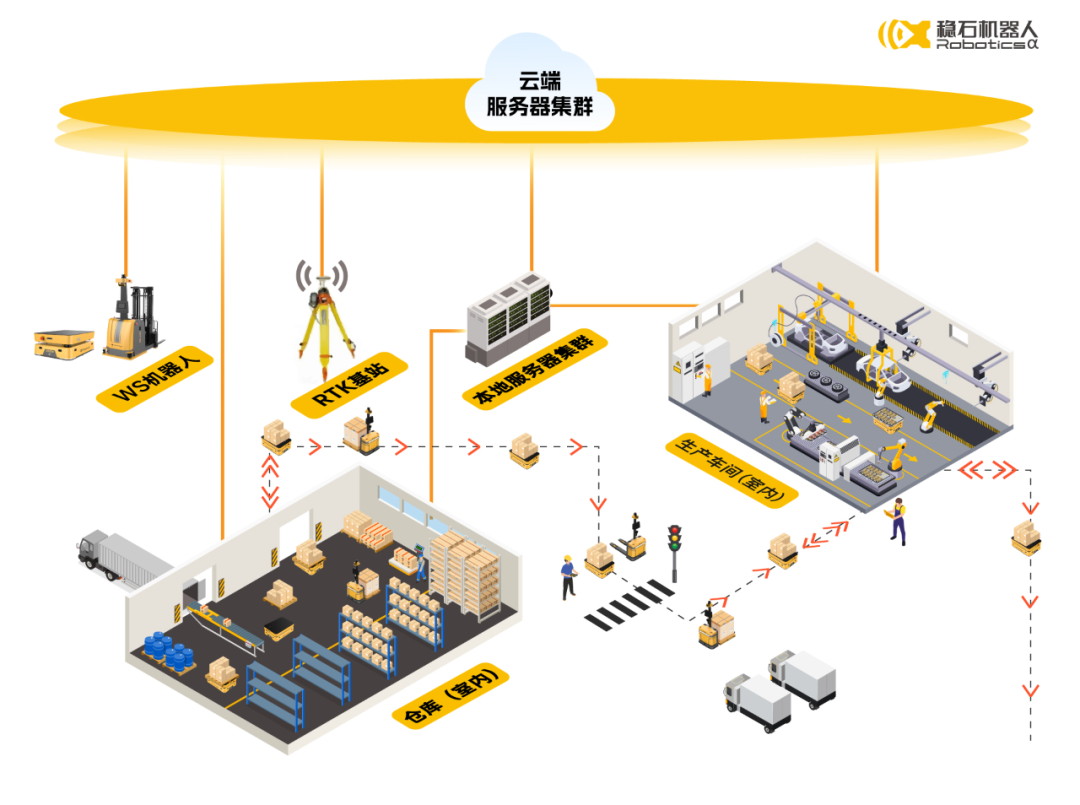

1. Scene "multimodal"

The "fifth generation multi-modal flexible AMR" robot adopts deep learning and automatic driving technology of high-performance GPU edge computing, and the robot can realize autonomous perception, segmentation and recognition of the scene.

The addition of high-performance GPU edge computing doubles the performance of the graphics and computing workflow with single-precision floating point (FP32), and doubles the bandwidth through PCIe 4.0, enabling advanced graphics and high-performance computing capabilities, and accelerating ray tracing and AI inference processes to provide high-performance computing and graphics processing capabilities. The addition of automatic driving technology enables the robot to continuously optimize its detection range, detection accuracy and detection capability in order to adapt to more edge scenes, so that the handling robot can "walk" out of the outdoor for the first time, which can not only meet the work needs of indoor open scenes, crowded and repeated scenes, narrow laneways, cross-layer transportation and other scenes. It can also meet the complex scene operations such as outdoor human-vehicle mixing and traffic intersections.

2.Business "multi-mode"

The new generation of products uses ChatGPT large model on high performance cloud computing for the first time to understand the instructions of advanced complex tasks and split the meta-operation, combined with the flexibility of structural design, to realize the flexible switching of multiple tasks of the body. The robot can complete multi-mode operations such as handling, loading and unloading, polishing and spraying, picking, laser marking, ground cleaning, and cargo counting. The whole process of raw material storage, warehouse management, assembly line operation, factory transfer and finished products out of storage is nearly unmanned management. In addition, for the first time, the new stone robot adopts a modular jacking installation design, which can be disassembled and replaced according to needs, so that a machine chassis can realize multi-function and multi-application scenarios fast switching.

3、Analysis of highlights

More powerful: it can replace accessories and coats as needed, and switch functions: loading and unloading, sorting, transportation, grinding, spraying, etc.

More abundant scenes: adapt to indoor and outdoor multi-scene, multi-production and storage applications;

The product is easy to use: easy to operate, easy to teach, lower the threshold, intuitive and efficient operation, shorten the project integration and debugging cycle, and equipped with UI interface, the body fault and solution prompt is clear and easy to understand;

The body is safer: Planning and design in accordance with CE safety standards, including full flame retardant housing, full flame retardant cables, dedetonation isolation of key components, battery optimization management, charging data detection, internal overcurrent, overvoltage, short circuit, high temperature detection and implementation programs, as well as personnel safety programs based on a variety of sensors, including safety contact, lidar, forward-looking camera and other safety means;

Higher cost performance: No matter what industry, cost reduction and efficiency is always a constant issue. Weishi robot has always been adhering to the lower cost, to provide customers with better performance and more safe and reliable products. Make the robot not only useful and easy to use, but also let more people use it;

Higher reliability: the parts and the whole machine have been strictly tested, meeting the wheel wear test of 20000km, meeting the jacking test of 200000 times, meeting the full load driving of 1000km and the vibration road test of 250km, and the high and low temperature environment test of -10℃-45℃.

The "fifth generation multi-modal flexible AMR" new product, which is about to be unveiled, has excellent performance, stable and reliable, the price is friendly to the people, and the return on investment cycle is less than 4 months, which is the ultimate expression of the stability stone robot in product inclusion and application breadth. It can be widely used in automobiles and parts, 3C electronics, daily chemical shoes and clothing, medical treatment, new energy and other scenes to help enterprises flexible production and quickly achieve cost reduction and efficiency.

There is no end to the road of innovation, and embracing change is the best way to cope with it. Wenshi robot has not only achieved the leadership of high-end excellent performance, but also achieved the scientific and technological inclusiveness in professional performance and price positioning. In the future, the stable stone robot will continue to challenge the "unprecedented", take the pulse of the market rhythm, resonate with the demand, and do the scene pain point solver. With faster product iteration, stronger scenario adaptation ability, and more extreme team execution ability, make the impossible possible!