2023 Double 11 strong start, according to star data statistics, this year's double 11 network turnover of 492.8 billion. Behind these data, is a huge warehouse in support, in the annual "double eleven" national shopping spree, the tide of general orders has brought huge business opportunities to enterprises, but also posed a severe challenge to manufacturing and logistics links, tens of thousands of goods in the warehouse ready to go, these warehouses in the party's "buy buy buy" offensive, how can it withstand.

The warehouse logistics system must be able to cope with the high intensity of work pressure to ensure the timely sorting of orders to the smooth delivery of Courier. Avoid situations such as untimely order processing, backlogged deliveries and misdeliveries, which can have a serious impact on consumers' shopping experience and brand image. Therefore, in the face of the joy and challenge of Double Eleven, the inner tangle and anxiety of e-commerce enterprises is understandable. For the common problems of double 11, see how the steady stone robot moves.

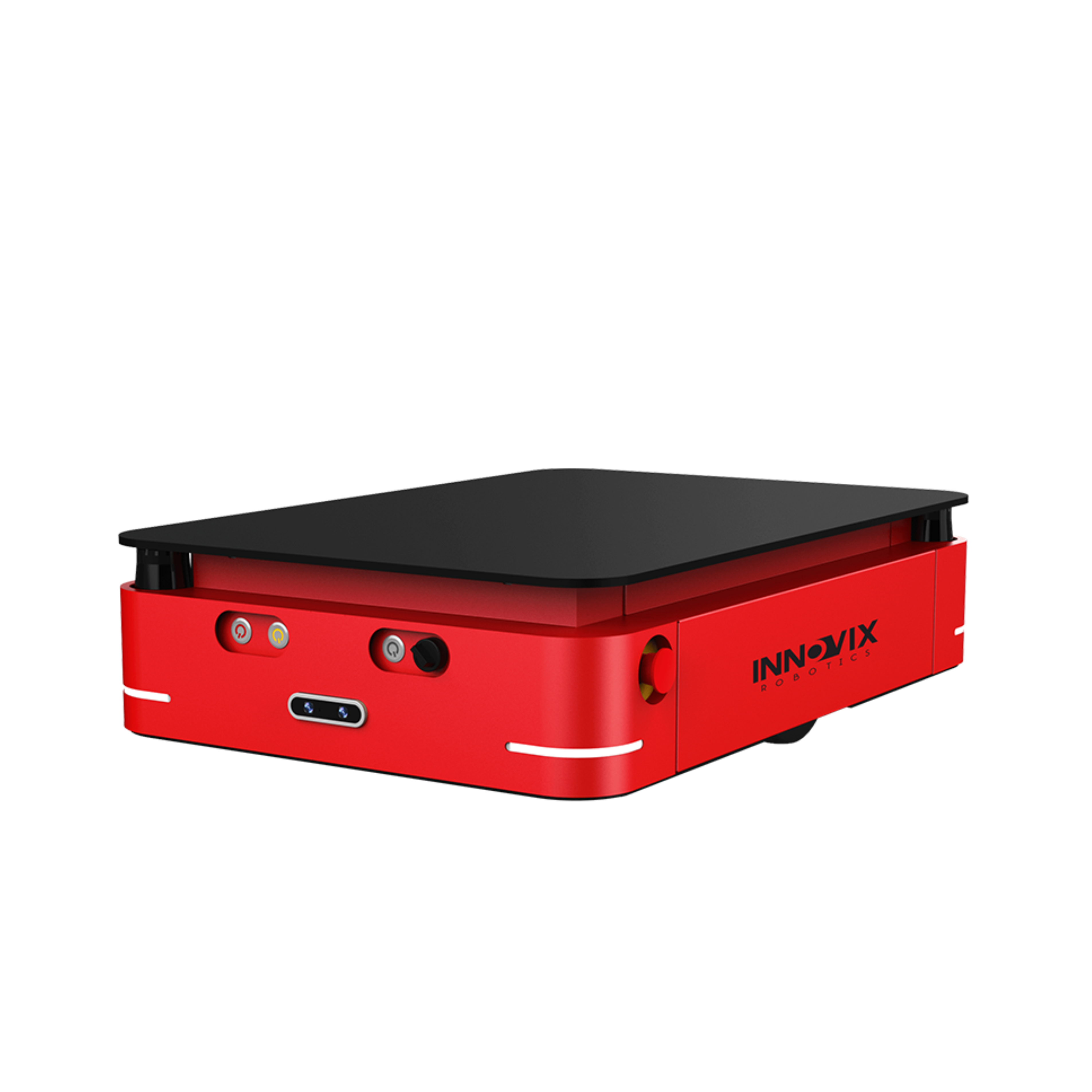

Orders surge, AMR batch!

Warehouse explosion is almost a hot word in double 11 every year, not only the explosion of their own warehouse, but also the phenomenon of insufficient transport capacity caused by the explosion of the carrier is not uncommon. The increase in stock stock means that more space is needed to store goods, and the increase in order volume means that more space is needed for operations: operation area space, warehouse inventory space, which brings great challenges to limited warehouse space.

The most time-consuming operation in the warehouse is walking and transportation. If the internal logistics transportation only relies on manual labor, it is not only inefficient and time-consuming, but also many repetitive labors are very boring, which is difficult to meet the extreme speed requirements of e-commerce enterprises and does not help employees satisfaction.

Taking on high-risk repetitive tasks through AMR allows skilled workers to spend less time on tedious tasks, allowing them to devote more time to higher-value work. This not only greatly improves the production efficiency to meet the requirements of users for speed in the era of e-commerce, but also improves the sense of accomplishment of employees.

Digital intelligent storage management system to solve the problem of diverse goods

On such a special day, consumers buy a variety of things, covering a wide range of goods and services. For the warehouse, to find goods quickly and accurately in thousands of categories, improve the efficiency of warehousing logistics, which requires e-commerce warehouses to use some intelligent means.

Taking the intelligent logistics solution launched by the stable stone robot as an example, in view of the low order processing speed and accuracy in the warehouse, the stable stone robot provides e-commerce enterprises with full automation services from order data to goods selection through deep learning and reinforcement learning technology.

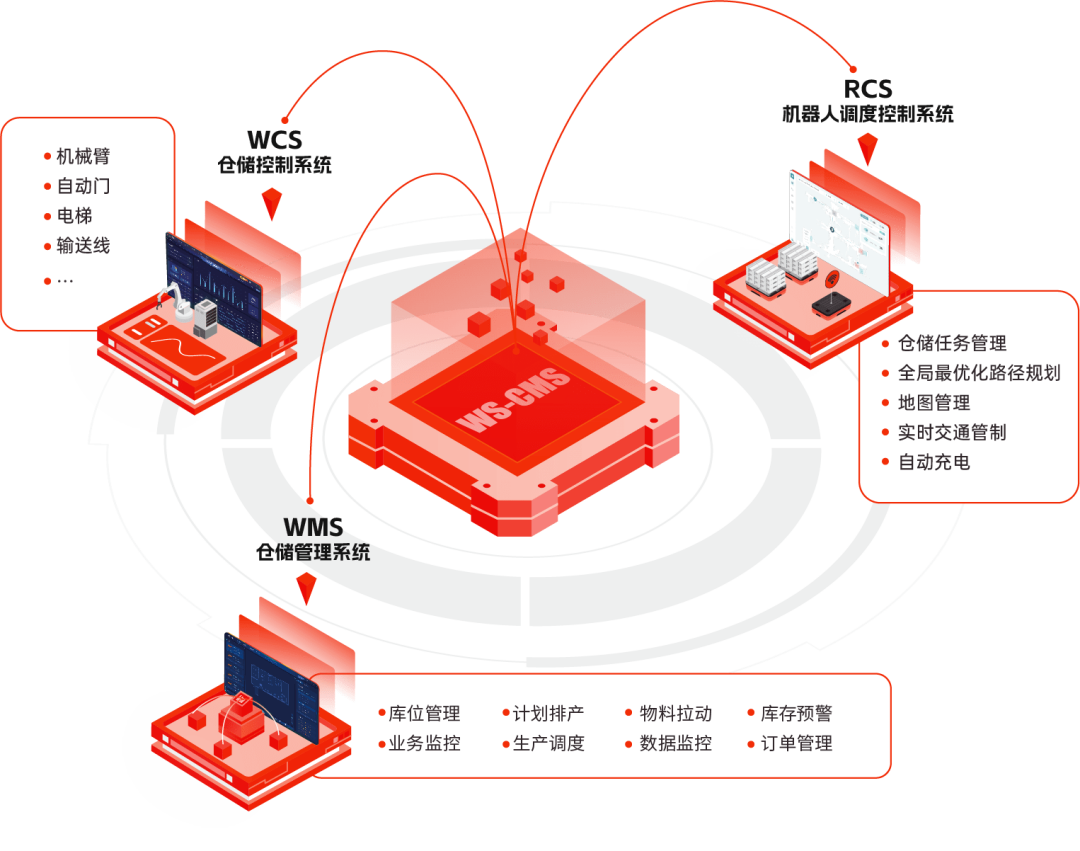

In the specific implementation, the robot first connected with the order system of e-commerce enterprises through the central management platform of the robot (WS-CMS) to obtain order data and analyze and process it. Then, the goods in the warehouse are accurately located through reinforcement learning algorithms, and AMR (autonomous mobile robot) is used to move the goods. Finally, deep learning technology is used to identify and classify the goods to ensure accuracy in the selection process. Through the introduction of intelligent technology, optimize the warehouse management process. It provides an efficient, accurate and low-cost solution for e-commerce enterprises to help them better meet the challenges in the Double 11 e-commerce carnival.

However, the pursuit of extreme efficiency can also come with some risks, such as an increased likelihood of injury in a fast-paced work environment. Therefore, optimizing the workflow of warehousing and logistics through intelligent upgrading is a necessary means to cope with the high pressure during e-commerce promotion activities.

AMR autonomous obstacle avoidance, employee safety!

While focusing on efficiency, e-commerce enterprises cannot ignore security risks. The mixed flow environment in the warehouse requires high safety. Many businesses use forklifts for transport, but such human-operated devices, controlled by split-second decisions, can be subject to human error, weigh three times as much as a car, and can reach speeds of up to 18 MPH, with a high risk of serious injury to staff in the event of an accident.

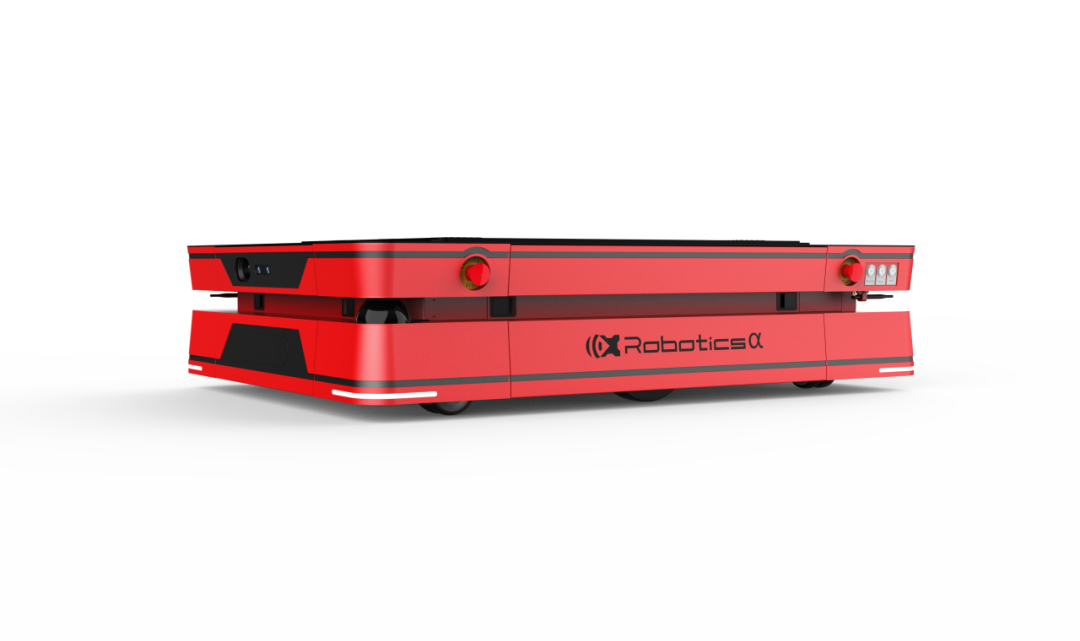

To address this security challenge, e-commerce business leaders are pinning their hopes on new technologies such as AMR. As a safe and flexible collaborative robot, AMR can replace some forklifts. The latest model WS-A1200LSE robot has a payload of up to 1200 kg and is CE certified at the highest level. It has protected enhanced components that can be dustproof and waterproof, suitable for multiple scenarios, and can solve the flexible transfer of materials across indoor and outdoor warehouses, transfer stations, and line side.

The WS-A1200LSE is equipped with the latest laser scanner technology, has a 360-degree all-round view, and scans from 30 to 2000 mm above the ground with two 3D cameras. The advanced configuration enables the WS-A1200LSE to dynamically sense the status of people and the environment in the work area and intelligently adjust vehicle movement, positioning, navigation actions and strategies. Automatically pick, transport and deliver pallets in a dynamic environment, navigate autonomously and choose the best route to avoid workers or obstacles, thereby reducing the risk of collisions and ensuring employee safety.

Take an e-commerce enterprise assisted by the Wenshi robot as an example, the e-commerce enterprise is a large-scale e-commerce platform with millions of registered users and tens of thousands of settled merchants. In order to improve user experience and optimize inventory management, the e-commerce platform has introduced 12 autonomous mobile robots AMR from Wenshi Robot. During the busy promotion period, the stable stone robot AMR can quickly process a large number of orders, avoiding the problem of slow manual processing speed and error-prone, effectively replacing more than 25 manual labor and improving the logistics storage efficiency of the warehouse by 50%. At the same time, the Steady Stone robot AMR can also intelligently identify error information in orders, reduce the return rate of orders, and improve customer satisfaction.

In addition to work efficiency, the steady stone robot also brings optimization of inventory management to the e-commerce enterprise. The e-commerce platform through the Wenshi robot distributed cluster management system + material management platform + customized vehicle interactive software, real-time monitoring of the inventory of goods, automatic replenishment, delivery, to avoid inventory overstock and out of stock problems. At the same time, the stable stone robot can also predict future sales trends based on historical sales data, providing a scientific basis for inventory planning.

In the face of increasingly fierce market competition, Weishi robot provides more comprehensive and personalized solutions for e-commerce enterprises through continuous technological innovation and upgrading. These solutions not only cover the entire process of e-commerce operations, but also customize development for the special needs of e-commerce enterprises to help enterprises achieve more efficient and accurate operational decisions.

In the future, Wenshi Robot will continue to deepen the e-commerce industry, and provide more high-quality and efficient technical services for e-commerce enterprises through continuous technological innovation and upgrading.