Traditional factories are transforming into smart factories. In response to the demand for more flexible and efficient automation applications, RoboticsAlpha launched a fully independently developed fifth-generation multi-modal flexible series of products at the end of 2023, which is compatible with indoor and outdoor scenes and serves as a platform for smart manufacturing integrators/ Industry terminals provide product portfolios such as mobile robot chassis, AMR, and unmanned forklifts with integrated controllers and digital software as the core.

The product embodies RoboticsAlpha's years of accumulation of robotics technology and understanding of future development trends. It has the advantages of flexible deployment, easy-to-use, safe and reliable, and extremely fast response. Based on innovative algorithm technology, it meets the needs of more flexible intelligent logistics solutions. Application requirements for complex scenarios in the fields of intelligent manufacturing and intelligent warehousing.

The fifth generation multi-modal flexible integrated controller

Super powerful algorithm innovation leadership

As the core component of a mobile robot, the controller is equivalent to the brain of the robot and is crucial to the robot's performance and operating efficiency. An excellent controller can not only ensure stable and efficient operation of smart equipment on site, but also reduce overall manufacturing costs.

RoboticsAlpha's self-developed fifth-generation multi-modal flexible integrated controller can realize AMR/unmanned forklift automatic navigation and driving through high-performance GPU edge computing capabilities. It can adapt to the working needs of all scenarios without modification and can be deployed within one week at the earliest. , the operation efficiency is higher.

Different from traditional controllers, special controllers for mobile robots have higher requirements for algorithm capabilities. RoboticsAlpha independently develops controllers using industrial-grade chips and is specially built for mobile smart devices. It can realize the functions of mobile devices under the same computing power. Significant reduction in consumption and costs.

Four core chips

Universal, high flexibility, low cost, low power consumption

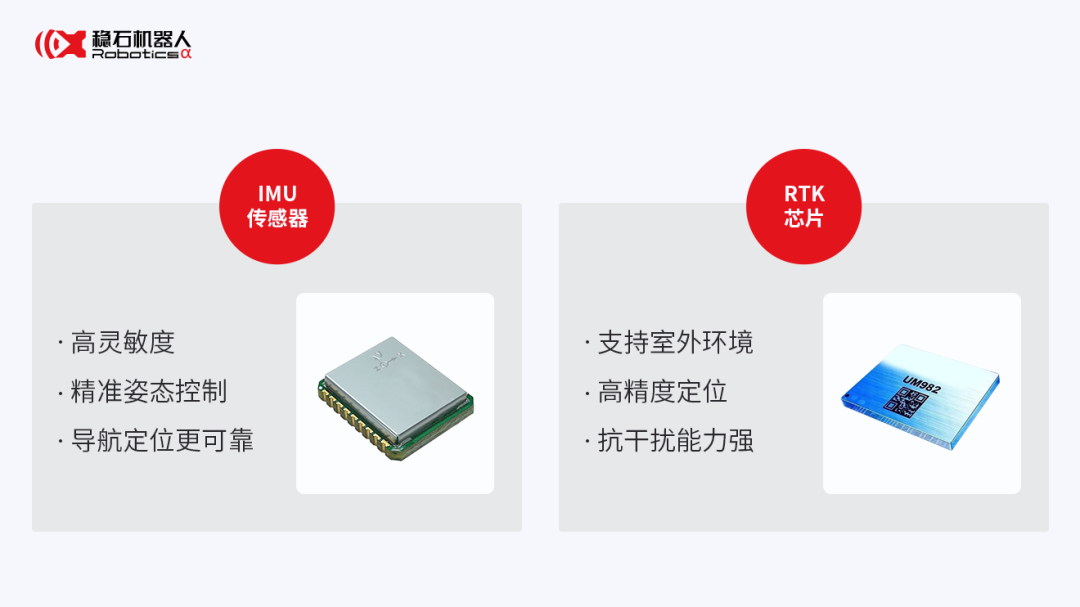

Accurate positioning and strong adaptability

• Multi-sensor fusion technology and self-developed asynchronous positioning fusion algorithm can output high-precision and high-stability positioning information, adapting to narrow/open, indoor/outdoor, high-brightness/high-dark environments.

• It has powerful secondary positioning capabilities and supports a variety of high-precision tasks, with an accuracy of up to 1mm±0.3mm.

Dynamic obstacle avoidance, safety protection

• Intelligent object recognition: Implement different strategies to avoid obstacles for objects in the scene, such as puddles, escalators, etc.

• Intelligent prediction of people and vehicles: Intelligent prediction of the movement of moving objects to achieve high-precision dynamic obstacle avoidance.

• Safe real-time path planning and obstacle avoidance: planning the motion trajectory of the traveling vehicle to avoid road obstacles.

Real-time perception, highly flexible

It has intelligent scene recognition and strategy capabilities, real-time perception of the environment, and dynamic adjustment of vehicle movement, positioning, navigation, etc.

Ready to use out of the box, extremely quick to configure

• Self-developed software architecture: Completely self-developed ROS-removing framework, with full control over details, ultra-high data channels, and ultra-low resource usage.

• Standardized product: It can be used quickly out of the box, adapts to a variety of operating mechanisms, and can realize multi-purpose material handling in one machine.

Fifth generation multi-modal flexible AMR/unmanned forklift

One machine with multiple functions for the ultimate experience

The operation of traditional AGVs mainly relies on deployed external markers, such as QR codes, magnetic strips, etc., making it difficult to flexibly respond to on-site changes. RoboticsAlpha products use laser and visual SLAM technology, as well as multi-sensor fusion technology, to achieve natural navigation and positioning, intelligent environment perception, autonomous path planning, automatic obstacle avoidance, etc., so they are more intelligent than traditional AGVs.

The fifth-generation multi-modal flexible AMR autonomous mobile robot is specially designed for multi-scene handling applications. Combined with unmanned forklifts, it can achieve full coverage from the ground to high-rise shelves. It can adapt to complex indoor and outdoor environments, resist interference from strong and weak light environments, and can empower people. More moving scenarios for enterprises.

Break through scene limitations and become more flexible

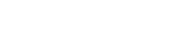

Light load type AMR WS-A300BSE

Heavy duty AMR WS-A1200LSE

Unmanned forklift WS-E2000BH

Based on the fifth-generation multi-modal flexible integrated controller, RoboticsAlpha released the AMR mobile robot chassis, light-duty AMR product WS-A300BSE, heavy-duty AMR product WS-A1200LSE, and unmanned forklift WS-E2000BH, with a variety of cargo capabilities The mode and load capacity can be flexibly deployed according to different cargo types and specifications.

No fear of complex environments

Match diverse business scenarios

RoboticsAlpha's various types of AMR/unmanned forklifts can solve various application problems for customers in a variety of business scenarios. They are also compatible with common indoor and outdoor road conditions, have strong climbing and obstacle capabilities, and can withstand the interference of outdoor strong light and light rain. Ensure the flexibility and safety of cargo transportation.

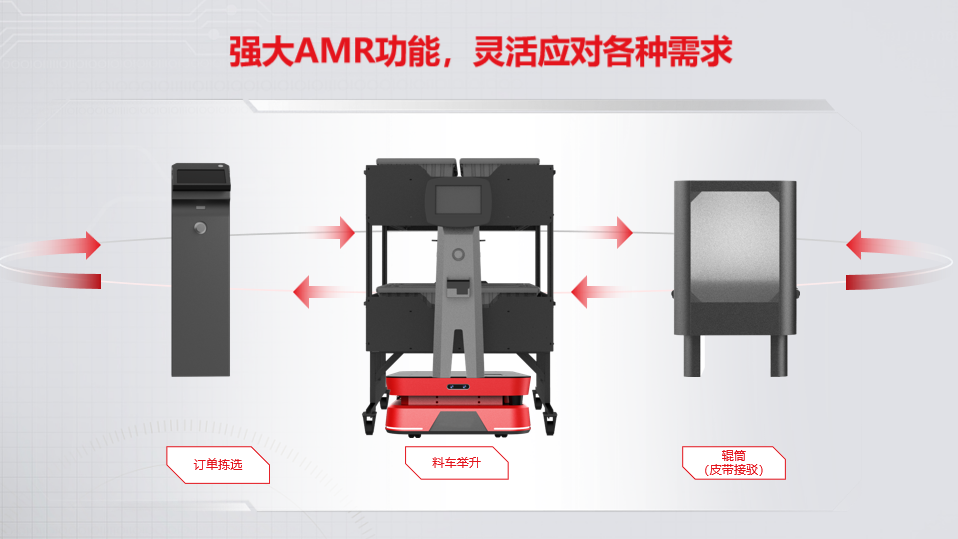

Flexible configuration of peripherals

Meet non-standard customization needs

RoboticsAlpha has a complete product and service system that supports multiple communication methods and peripheral docking, and can quickly adapt to upper-level business systems for data interoperability and information sharing; the machine can be equipped with an upper-layer structure to realize roller docking, jacking and other capabilities. Solve manufacturing problems when meeting non-standard requirements and expand the scope of applications.

Software and hardware integration

Achieve high-density and efficient storage

RoboticsAlpha fifth-generation multi-modal series of products, combined with the independently developed distributed cluster scheduling algorithm/storage location management algorithm, can realize collaborative operations and intelligent scheduling between multiple, multiple, and multiple robots, improving the efficiency of warehousing and logistics. and flexibility, covering all aspects from the ground to high-rise shelves.

RoboticsAlpha fifth-generation multi-modal series products and its comprehensive flexible logistics solutions can cover 20+ application scenarios in daily chemicals, auto parts, 3C, food, medicine, 3PL and other industries, saving 50% on traditional warehouse operation modes. -70% labor cost, and can effectively improve efficiency, reduce wrong order rate, product loss rate, etc., thus significantly reducing warehouse operating costs.