What happens when an industrial robot loses its 'brain'?

Signal interruption, robot execution failure, like a fly in the headless around the plant;

Failure rate continues to increase, always "turning over" at critical moments, crashing and locking problems occur frequently;

......

With the rapid development of industrial intelligent logistics, industrial robots are increasingly becoming an indispensable role in automated production lines and intelligent logistics systems. However, the deepening of application scenarios, different generations of industrial robots in the complex industrial site also frequently appear "not suitable for the soil". The root cause of these problems is often closely related to the robot's "brain" - the performance of the controller.

The controller is the key to a robot's performance, determining its responsiveness, ease of operation, deployment efficiency and operational stability. Today, we will discuss this core component that is crucial to industrial robots, analyze how the controller affects the robot's performance from the working principle to the development of the technology, and explore how to solve the existing challenges through technological innovation to promote the development of industrial robotics to a higher level.

Controllers.

Determining the "IQ" of industrial robots

As the "brain" that gives robots their functions and behaviors, the controller of industrial robots is one of the three core components of the entire robot system. According to the data compiled by China Business Industry Research Institute, the controller accounts for about 15% of the cost of industrial robots.

The controller not only determines the performance of the robot, but also accurately controls its position, attitude, trajectory, as well as the timing and sequence of actions in the workspace, just as human beings rely on their brains for thinking and decision-making.

In practical applications, the controller translates complex operating instructions into precise robot movements, adapts quickly to changes in the external environment through real-time processing of sensor data, ensures the accuracy and efficiency of each operation, and enables the robot to flexibly respond to a variety of complex production tasks.

And with the rapid development of AI and IoT technologies, the refinement of industrial scenarios and the increase in demand for mobile robot intelligence, more and more head companies are introducing the industry's technological innovations into controllers, such as AI algorithms, the latest calibration technology, safety protection technology, etc., which drive controllers toward a higher degree of integration and safer and easier to use. It can be said that the controller defines the capability boundary of industrial robots.

controllers.

Driving the "Evolution" of Industrial Robots

The successive innovations in industrial robot controllers have led to a generational revolution in industrial robotics.

In 1972, Kollmorgen AGV launched the first generation of ACC series vehicle controllers, marking the birth of the industrial robot controller industry. In the early days, the industry relied on microcontroller and PLC technology, AGV/AMR special controllers have not yet been molded, mostly assembled control components. The controllers in this period had shortcomings such as limited algorithmic capability, high cost, single function, high development cost, lack of stability and large size, and there was still a large gap between them and commercialized standard products.

In 2012, with the two-dimensional code navigation robot in the field of e-commerce began to scale application, the controller industry has also entered the era of special machine. Controllers in this period have more complete algorithms at the perception, decision-making, and execution levels, and practical application experience has also contributed to the improvement of controller performance. However, the navigation method mainly relies on QR codes, magnetism, reflectors, etc., resulting in a relatively fixed driving path and relatively low demand for decision-making execution algorithms.

Around 2016, the emergence of standard product controllers centered on SLAM navigation opened a new era of AMR-specific controllers. This generation of controllers already has the advantages of high integration, multi-functionality, high performance and ease of use, incorporating vision and other perception technologies, providing more flexible path planning and more flexible function realization, and requiring higher algorithms.

The White Paper on Intelligent Robotics Industry Development points out that intelligent robotics technology is rapidly evolving towards deep intelligent drive, efficient virtual control, ubiquitous agile operation and multiple sensory interactions, in which the controller, as one of the core components of intelligent robots, plays a crucial role.

With the deepening of mobile robot applications, controller manufacturers continue to iterate their products to meet market demand. A new generation of controllers equipped with AMR, a high-performance GPU edge computing/autonomous driving technology, was birthed. This controller can meet the needs of customers for industrial robots working in all scenarios, and compared with the previous generation controller, it can also realize a faster deployment cycle, meet the needs of more complex business scenarios, and provide customers with more peace of mind.

Controller

Promoting "Autonomous Innovation" in Industrial Robotics

According to IFR, the installed base of industrial robots in China has been growing steadily in recent years, making it the world's largest industrial robot market. However, it is still highly dependent on imports for core components, especially controller technology.

The "2023 China Industrial Robot Controller Industry Competitive Landscape and Market Scale Prospect Analysis" report points out that the maturity of domestic enterprises in the key technology area of controller is still insufficient, which not only leads to the higher cost of domestically produced robots, but also puts them in an unfavorable position in the market competition with foreign-funded brands, which then affects the potential of domestically produced robots to play a role in the production and application of a larger scale.

For a long time, the main share of the domestic industrial robot controller market has been occupied by the United States, Japan, South Korea and other foreign manufacturers. These manufacturers rely on their leading position in core technology to establish a dominant position in the market and enjoy a strong reputation worldwide.

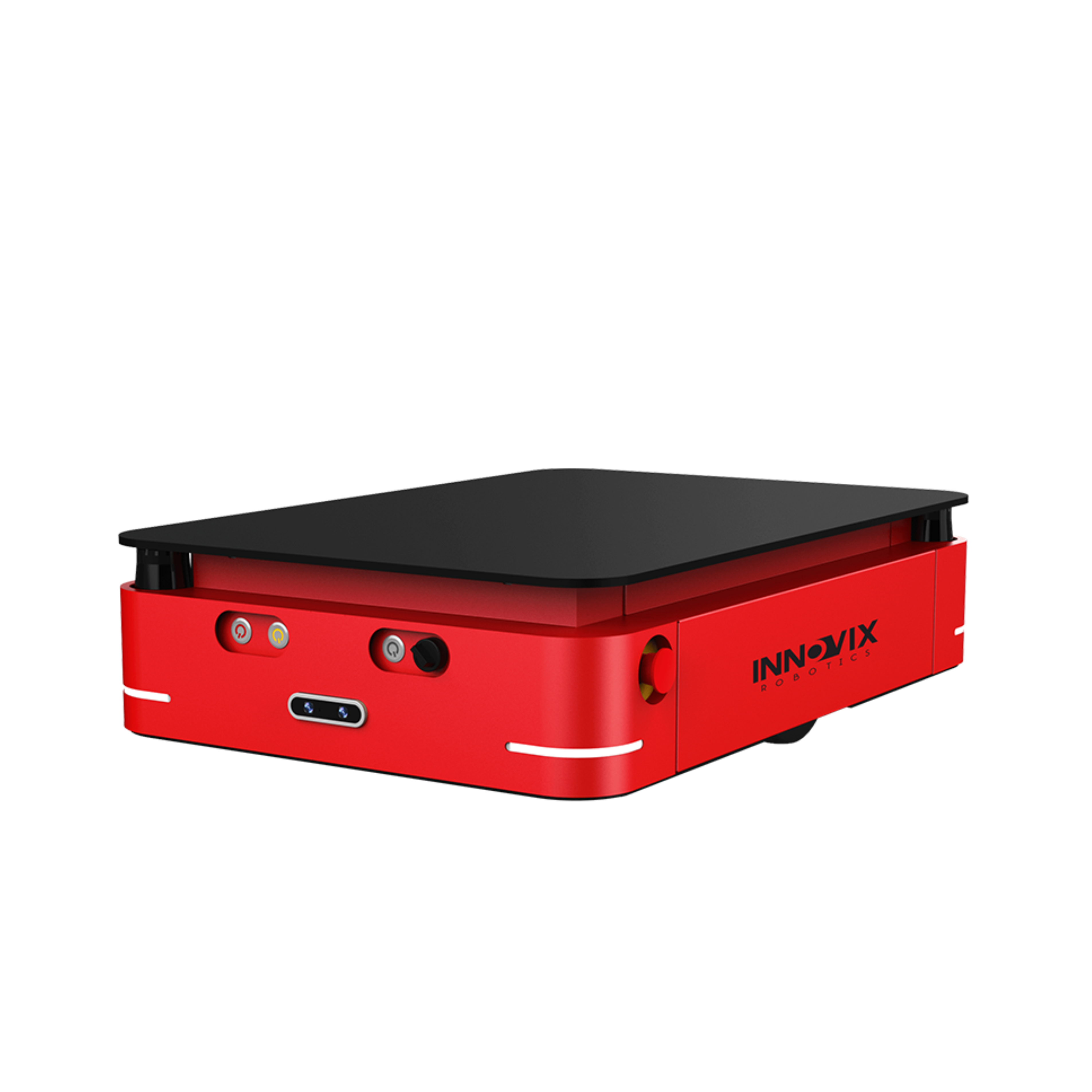

The continuous progress of technology has brought new opportunities for the development of industrial robot controllers in China. Take Innovix Robotics self-developed fifth-generation multimodal flexible integrated controller as an example, the product adopts high-performance GPU edge computing technology, providing advanced automatic navigation driving capabilities for AMR and unmanned forklifts.

This controller is not only highly flexible and adaptable, able to quickly adapt to various working environments, but also easy and fast to deploy, the fastest time is only 1 week, which significantly improves the operational efficiency.

The breakthrough in related technology not only demonstrates the innovation ability of domestic enterprises in the field of controllers, but also provides strong support for domestic industrial robots to enhance their competitiveness in the global market. With the deepening of China's independent innovation, it is believed that more similar new technologies will continue to emerge, and domestic industrial robots will be more widely used in the near future, contributing to the high-quality development of China's industry.