Comprehensive solution for full-scene flexible logistics

Helping Coating Manufacturers Transform Logistics with High Quality

China is the world's largest producer and consumer of coatings, and with the rapid iteration of the market, the requirements for products and technologies are getting higher and higher. For coating manufacturers, how to grasp the development opportunities of the market, accelerate the efficiency of production capacity, improve product quality and reduce operating costs through new technologies has become an important key to enhance the competitiveness of enterprises.

The customer is a well-known powder coating manufacturer, mainly producing wood grain powder coating and wood grain transfer paper, with 8 branch factories and more than 30 advanced powder coating and wood grain paper production lines.

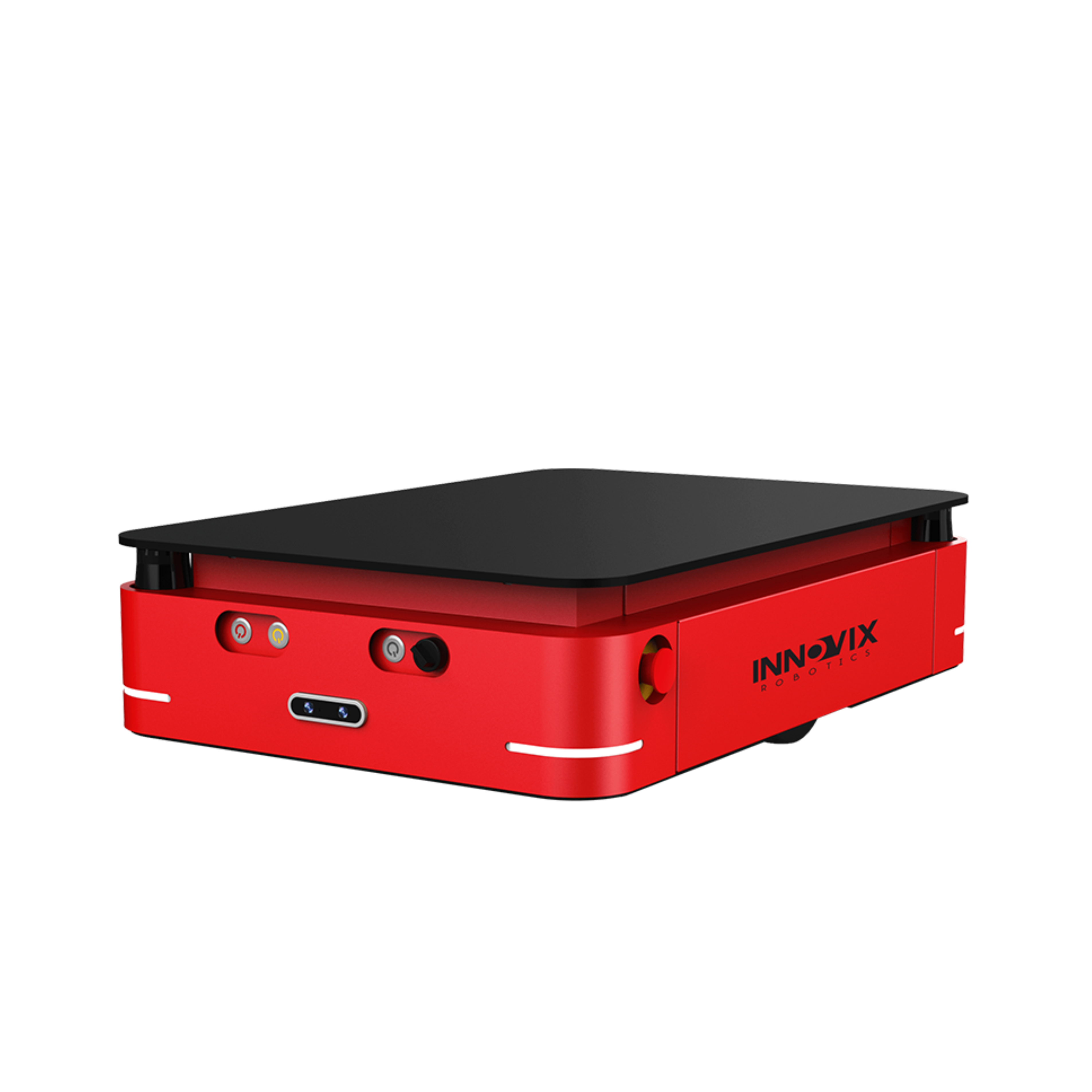

Under the current trend of intelligent transformation and upgrading, the customer chose to cooperate with Innovix Robotics to greatly improve the efficiency of warehouse access and realize digital logistics management by deploying highly flexible unmanned forklift solutions.

Customer Pain Points

Difficulties in traditional handling mode

The factory originally used the traditional manual handling mode, on the one hand, the working environment is harsh, the workshop is dusty, and the labor intensity is high; on the other hand, the manual efficiency is low, the information of the goods in and out of the warehouse is difficult to trace, and the enterprise's labor management cost is high.

Under the current trend of intelligent transformation and upgrading, the enterprise needs a more cost-effective flexible logistics solution to replace the traditional manual handling, so as to realize more efficient warehousing and digital operation management.

Solutions

Robot full-process automated handling

The introduction of “forward moving unmanned forklift” as the hardware carrier, combined with Innovix Robotics i-WMS warehouse management system, RCS robot scheduling system, intelligent logistics solutions, to realize the coating manufacturing plant materials from the metal powder ground warehouse, semi-finished products ground warehouse to the finished product warehouse of the whole process of automation. It greatly improves the efficiency of warehousing, saves labor cost and helps the enterprise to reduce cost and increase efficiency.

The project involves both indoor and outdoor scenarios, from indoor to outdoor, the robot needs to cope with more complex problems, such as outdoor navigation and positioning, weather emergencies and so on. Steady Stone's robotic products are equipped with advanced laser SLAM + vision fusion navigation technology, which can adapt to complex environments, autonomously plan the optimal path, and efficiently link up indoors and outdoors.

In addition, the forward-moving unmanned forklift has the function of lifting up to 9m, which greatly improves the utilization rate of warehouse space. Combined with the self-developed distributed cluster scheduling algorithm/storage management algorithm, it can realize cooperative operation and intelligent scheduling between multiple robots and many robots, which improves the efficiency and flexibility of warehousing and logistics.

Project Effectiveness

Helping enterprises reduce costs and increase efficiency

01Improve the efficiency of warehousing

Realize automatic goods in and out of the warehouse, unmanned operation of the robot 24 hours to improve the efficiency of factory logistics.

02Save labor costs

The robot replaces 4 laborers, reduces labor intensity, wrong order rate and product loss rate.

03Digitalized management

Realize the traceability tracking of cargo data, enterprises can always grasp the progress of logistics, so that the management is more transparent and convenient.

04Improve the rate of storage capacity

From the ground to the full range of overhead shelves to meet the needs of enterprises for high-density storage and efficient access to the warehouse.

Innovix Robotics' high-quality robotic products and industry solutions have been widely used around the world, significantly improving logistics efficiency and production quality. In the future, Innovix Robotics will continue to empower enterprises to realize intelligent upgrading under the dual-wheel drive of technological innovation and global layout.