In 2024, “new quality productivity” has become a hot word.

The State Council's 2024 government work report proposes to vigorously promote the construction of a modernized industrial system and accelerate the development of new productivity. What is new quality productivity? Simply put, it refers to the ability to realize the overall improvement of production mode, production efficiency and product quality through technological innovation, production factor allocation and industrial transformation and upgrading.

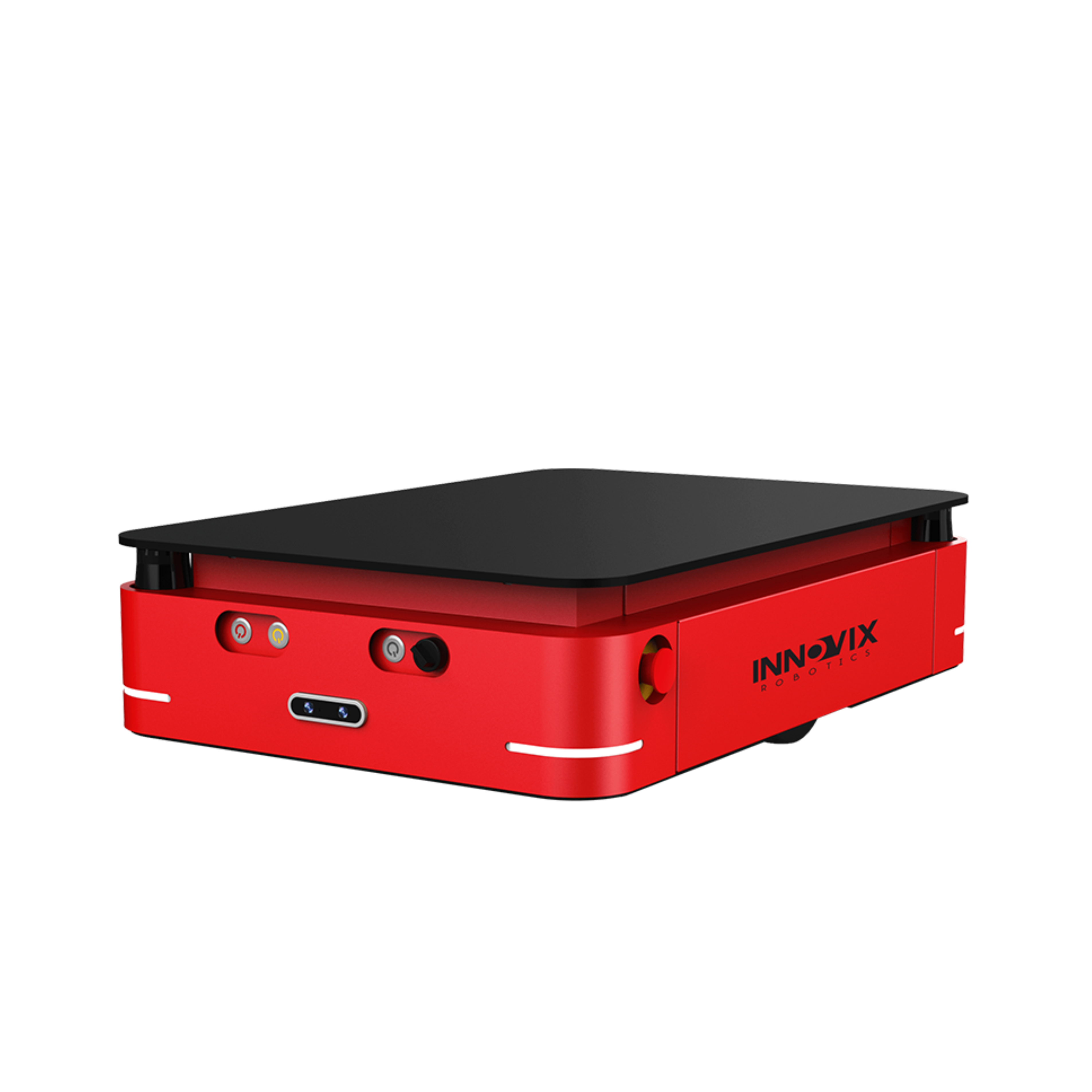

Compared with traditional productivity, new quality productivity involves new fields, high technology content, relying on innovation is the key. Industrial robots are different from the traditional growth mode, with high-tech, high-efficiency, high-quality and other industry characteristics. Innovix Robotics, a National High-tech enterprise with science and technology innovation as its core, perfectly fits the essence of new quality productivity.

Robot technology and product application

Injecting innovative kinetic energy into industrial development

In today's industrial field, mobile robot products and technologies are widely used in various logistics scenarios, becoming one of the core driving forces for industrial upgrading. Innovix Robotics, as a leading provider of comprehensive solutions for full-scene flexible logistics in the industry, focuses on industrial logistics scenarios with new technologies, new algorithms, and new hardware, combined with a full-scene product line of intelligent logistics equipment. With new technologies, new products and new applications, Innovix Robotics injects innovative kinetic energy into thousands of industries.

New quality productivity empowers industrial logistics, and cutting-edge technology and application scenarios run in both directions, which is not only the keen insight and active response of enterprises in the face of market changes, but also the driving force for Innovix Robotics to continuously innovate its technology.

Among them, algorithm technologies such as “Dual LIDAR+Vision Fusion Navigation” and “Optimized Dynamic Path Planning” can help robots adapt to changing industrial environments and be more efficient and safer; “RCS Robot Control and Scheduling System” and “iRobot Control and Scheduling System” can help robots adapt to changing industrial environments and be more efficient and safer. RCS Robot Control and Scheduling System” and ‘i-WMS Warehouse Management System’ can be efficiently interconnected with other logistics equipment and warehousing equipment to open up the data chain of intelligent factories;

The latest product “5th generation multi-modal flexible controller/AMR/unmanned forklift” can realize flexible self-adaptation of robots in complex dynamic scenarios and flexible universal capability of complex operation tasks, and realize the integrated solution of flexible logistics in warehouse and storage through the pioneering “AMR+unmanned forklift” whole scenario. Through the pioneering “AMR + unmanned forklift” comprehensive solution of flexible logistics, it realizes the automated operation of all aspects of warehousing and production logistics.

Full-scene flexible logistics solution

Promote the upgrading of traditional manufacturing industry to new

The “new” of new quality productivity not only refers to original and disruptive innovation, but also the upgrading of traditional manufacturing industry. Under the background of “intelligent transformation and digital transformation”, Innovix Robotics full-scene flexible logistics solution provides a powerful impetus for the upgrading of the internal logistics of factories with its high efficiency and accuracy, and the digital management of the whole chain of logistics in factories effectively improves the overall efficiency and quality of collaboration to help enterprises get rid of the sloppy management mode. enterprises to get rid of the sloppy management mode and move forward to a new industrial revolution.

In the daily chemical industry, Innovix Robotics helps the global head daily chemical enterprise to upgrade its whole-scene intelligent logistics, from the trial run of the first vehicle in the Chinese factory to the application of robots on the ground in the factories in many countries, creating a replicable industry solution with localized characteristics and in line with the stringent international standards for the enterprise;

In the 3C industry, Innovix Robotics has helped technology giant supply chain enterprises realize large-scale deployment of robots, efficiently connecting the whole process of picking, handling and storage, significantly reducing picking time and achieving record high storage capacity; in the footwear and apparel industry, the pharmaceutical industry, and the chemical industry ......Innovix Robotics promotes quality with newness, promotes the deep integration of robotics and industrial development, and creates a multiplier effect of both efficiency and productivity for the manufacturing industry.

Relying on the industry's top experts and a team of technical elites, Innovix Robotics has served nearly 100 companies, covering 20+ industry scenarios, and cooperating with many Fortune 500 companies and large industrial customers, with projects covering industries such as daily chemicals, medical, 3PL, footwear, electronics, etc.

Nowadays, the new quality productivity has become an important force to promote the transformation of industrial digital intelligence, cutting-edge technology with unprecedented speed to make the production possibility curve constantly jumping up, Innovix Robotics will continue to plough into the industry, adhere to the independent innovation technology, and drive China's industry to a new stage with the globalization of the sales, operation and service capabilities.