In recent years, the rapid development of the daily chemical industry, to “clean class” and “cosmetic products” mainly in people's lives play an indispensable role. However, in the process of development, many difficulties have begun to show their heads, difficult to recruit workers, expensive labor, production speed constraints, and other difficulties, all of which pose a challenge to the sustainable development of daily chemical enterprises.

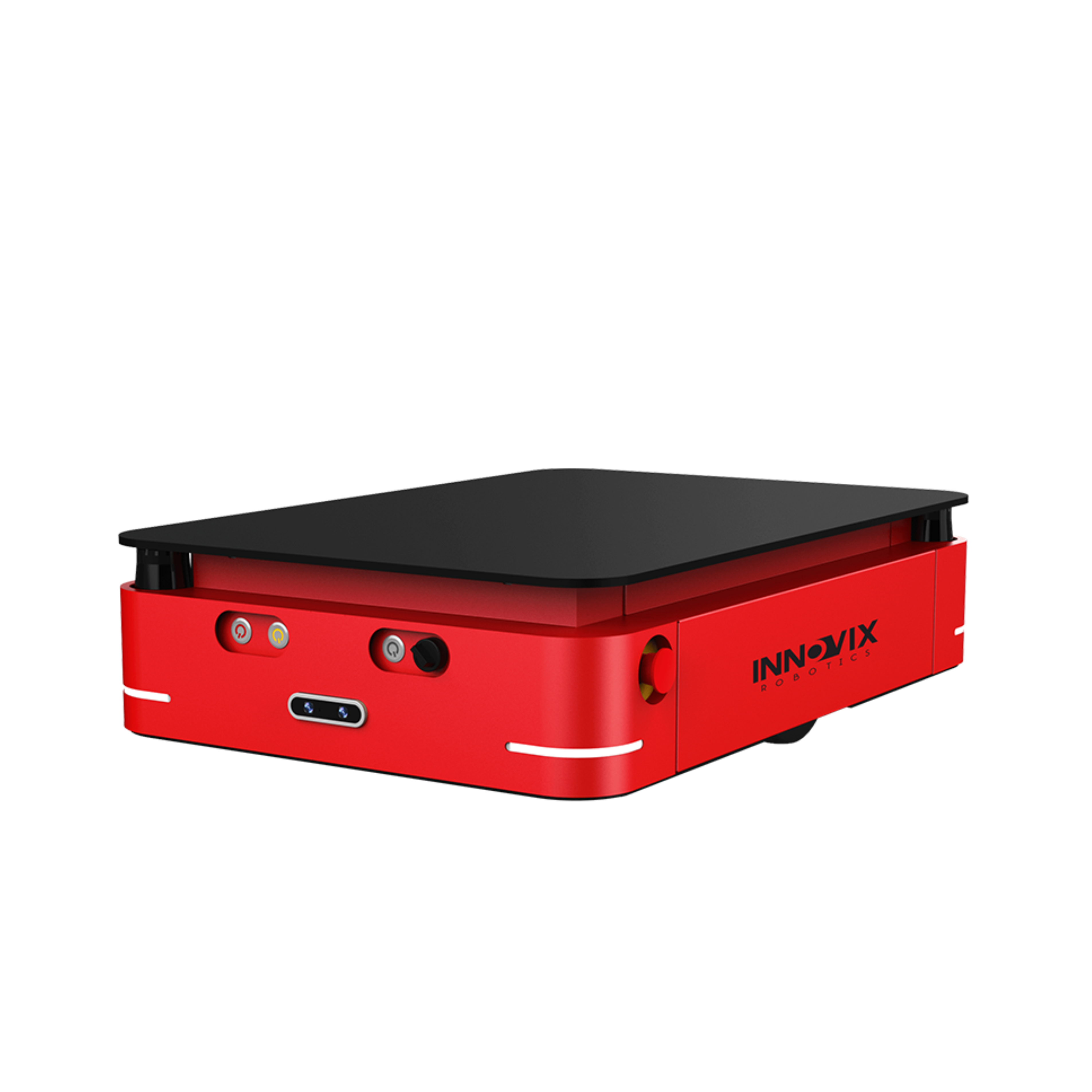

To cope with these challenges, this famous daily chemical company chose to cooperate with Innovix Robotics and introduced several Innovix Robotics AMR S1200L to improve the efficiency and flexibility of production and warehousing logistics with intelligent logistics solutions.

Project Background

The customer is a large domestic daily chemical enterprise integrating independent R&D, production and sales, and its products are exported to more than 90 countries and regions, such as the United States, Canada, the United Kingdom, Australia, Russia, etc., especially in the field of oral care and household cleaning care products with high market awareness.

Diversified market demand for daily chemical enterprises production equipment to put forward more “function” and “performance” requirements, the need for enterprises to quickly respond to market changes, the traditional artificial logistics model has been unable to cope with daily chemical enterprises growing capacity needs. Innovix Robotics intelligent logistics solutions to replace the “automated equipment + manual” mode, from simple, repetitive operations to free manpower, will further optimize the efficiency of production line operations, to achieve more sophisticated inventory management and logistics coordination, to promote the digital transformation of factories.

Solutions

To meet the specific needs of the daily chemical industry, Innovix Robotics provides multiple AMR S1200Ls, which are equipped with a 1200kg load capacity, advanced laser SLAM navigation technology, and the ability to adapt to changing logistic environments, providing strong support for internal logistics handling.

It not only realizes autonomous path planning and obstacle avoidance to ensure safe and efficient cargo handling in complex scenarios where people and vehicles are mixed together, but also improves the overall logistics efficiency by integrating the advanced robot cluster scheduling system and seamlessly connecting with the existing warehouse management system to realize real-time monitoring and analysis of data.

Application Effectiveness

Since deploying the AMR S1200L, the company has realized a 3-5 times increase in efficiency in production and warehouse logistics. The autonomous navigation and handling capabilities of the robots have reduced manual operations and lowered labor intensity, while improving the accuracy and safety of operations. During peak business periods, AMR S1200L's flexible scheduling capability effectively responded to fluctuations in order volume, dramatically speeding up the process by more than 40% compared to manual shipping methods, and improving customer satisfaction.

“Innovix Robotics' mobile robots have enabled us to realize the change from traditional manual to machine-automated execution of tasks, solved the low efficiency drawbacks of the production line in the previous decades with intelligent logistics, overcame the damage to the products brought about by the previous material transportation process, and broke through the bottleneck of product production efficiency and capacity. -Customer Comments

Innovix Robotics has been recognized and trusted by the industry for providing efficient and flexible automation solutions for the storage and logistics industry, with more than 80% of major customers choosing to repurchase. In the face of the trend of more efficient storage and management, Innovix Robotics will provide customers with faster and more accurate services, and continue to empower customers to realize digitalization and intelligent upgrading.