In the wave of global industrial innovation, intelligent logistics is becoming one of the core driving forces for the transformation and upgrading of the manufacturing industry. Highly flexible intelligent logistics solutions can help enterprises cope with complex logistics challenges and realize the intelligence, flexibility and high integration of the whole process from production to warehousing, bringing significant economic benefits.

As the industry's leading comprehensive solution provider for full-scene flexible logistics, Innovix Robotics is just like the “Man of Destiny” in the “Black Myth: Goku”, who, through cutting-edge robotics technology, products and intelligent algorithms, performs the “three heads and six arms” in various industries, providing enterprises with solutions from production to warehousing. Through cutting-edge robotics technology, products and intelligent algorithms, the “Man of Destiny” in “Goku” is able to perform “three heads and six arms” in various industries, and provide enterprises with all-round services from design, implementation to maintenance. Together with Innovix, we will write a new “black myth” of intelligent logistics in various industries.

Daily Chemical Industry

The customer is a large domestic daily chemical company, facing the challenges of diversified market demand and capacity growth, introduced Steady Stone AMR S1200L robots, which are seamlessly connected with self-developed scheduling system and warehouse management system, improving logistics efficiency by 3-5 times, increasing shipping speed by more than 40%, and assisting in digital transformation of factories.

The company is one of the world's largest consumer of daily necessities, and has cooperated with Innovix Robotics to land robot applications in several factories in China, Japan, Korea, North America, Europe and Southeast Asia, realizing a 4-fold increase in picking efficiency, handling efficiency and storage efficiency, significantly shortening the picking time, and achieving record-high storage capacity.

Footwear Industry

At the footwear and apparel factory of a leading Chinese sporting goods company, AMR took over non-value-added internal transportation tasks to optimize productivity. Employees are freed from tedious and repetitive tasks to perform higher-value work.

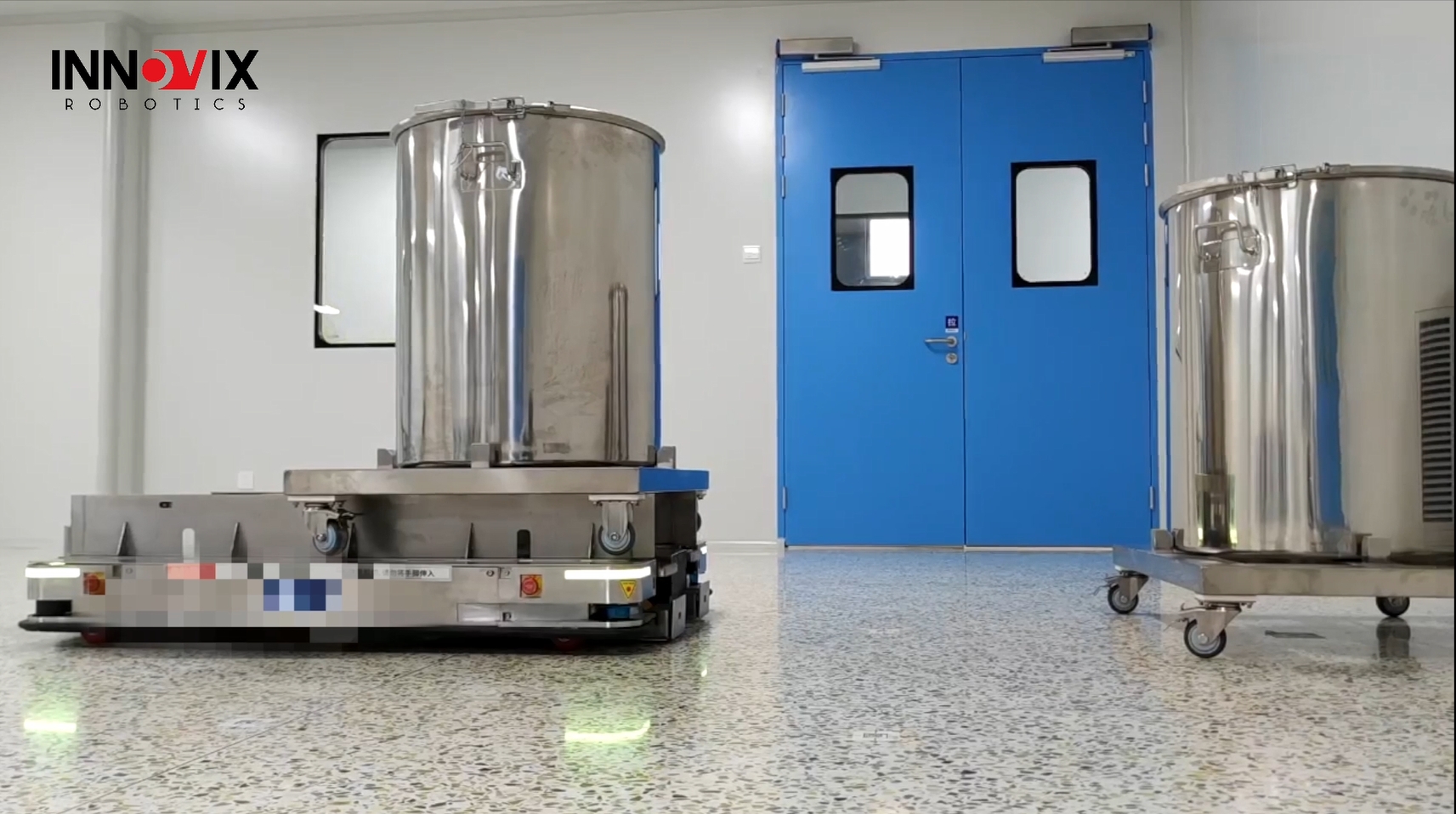

Pharmaceutical Industry

A leading pharmaceutical company in China introduced Innovix Robotics to automate the handling of pharmaceuticals from the production line to the warehouse in response to stringent drug traceability requirements. The system is seamlessly integrated with the enterprise MES to ensure the traceability of the whole process of pharmaceuticals, and at the same time, it improves the logistics efficiency by more than 2 times, reduces human errors, and ensures the safety of pharmaceuticals.

Chemical Industry

The well-known powder coating manufacturer adopted Innovix Robotics' unmanned forklift and intelligent logistics system to automate production logistics. It adapts to indoor and outdoor environments, improves the efficiency of inbound and outbound storage, and saves labor costs. After the implementation of the project, the logistics management is digitalized and the warehouse capacity rate is increased, which significantly promotes the intelligent transformation of the enterprise.

Food Industry

Facing the challenges of food perishability, fluctuating demand and food safety standards, this agri-food processing plant adopted Innovix Robotics AMR to realize heavy-duty flexible handling. The solution improves logistics efficiency, with 100% timeliness of material supply, a 3-fold increase in inbound and outbound efficiency, and a more than 40% reduction in labor requirements, significantly reducing costs and increasing efficiency.

Third party logistics industry

The customer is a well-known third-party logistics company in China. In order to improve the efficiency of warehouse management and the speed of goods flow, it deploys multiple Innovix Robotics to realize efficient and accurate goods picking and distribution. After the implementation of the project, the efficiency of logistics operations was increased by 3 times, the error rate was significantly reduced, the customer service experience was effectively optimized, and the automation and intelligent development of the logistics center was promoted.

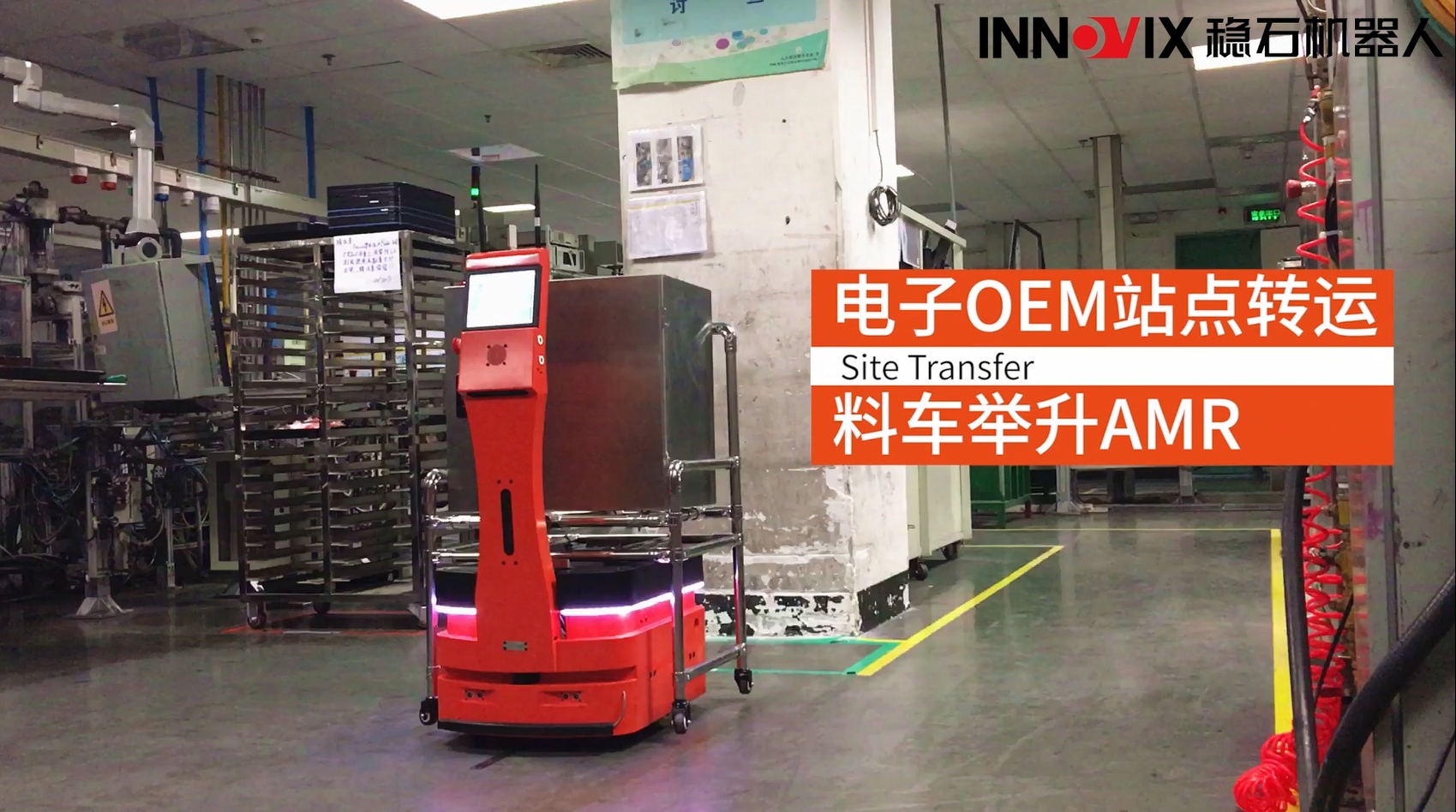

Electronics Industry

The customer is the world's largest electronics manufacturer. In cooperation with Innovix Robotics, multiple robots efficiently plan paths, greatly optimize picking steps, and reduce operation time, which perfectly fits the customer's requirements for improving order processing efficiency, and significantly improves the degree of flexibility and automation in production.

In today's fast-moving industrial era, Innovix Robotics has demonstrated its strong ability to provide full-scenario intelligent logistics solutions in a variety of industries with its innovative robotics technology. From daily chemicals to footwear, from pharmaceuticals to chemicals, to food and third-party logistics, it not only improves operational efficiency, but also brings higher operational transparency and stronger market competitiveness to enterprises.

With the continuous progress of technology and the expansion of application scenarios, Innovix Robotics will continue to promote the development of Industry 4.0, help more enterprises realize intelligent and automated logistics management, and create a better future of intelligent logistics.