With the rapid advancement of artificial intelligence and robotics, increasingly efficient and intelligent solutions are emerging in the field of automation. Among them, hybrid robots, which integrate multiple functions such as "hands, eyes, feet, and brain," excel in handling more precise and complex tasks.

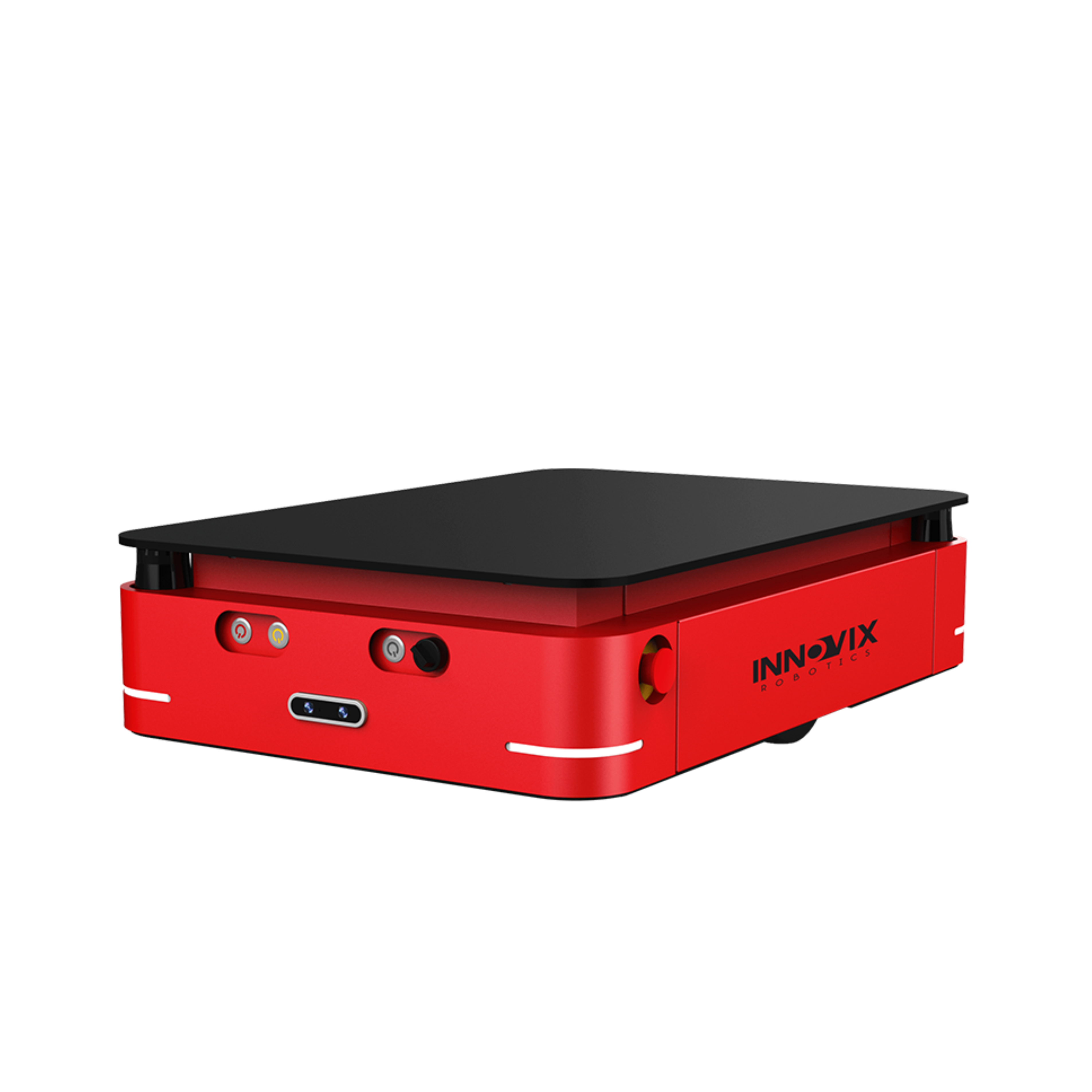

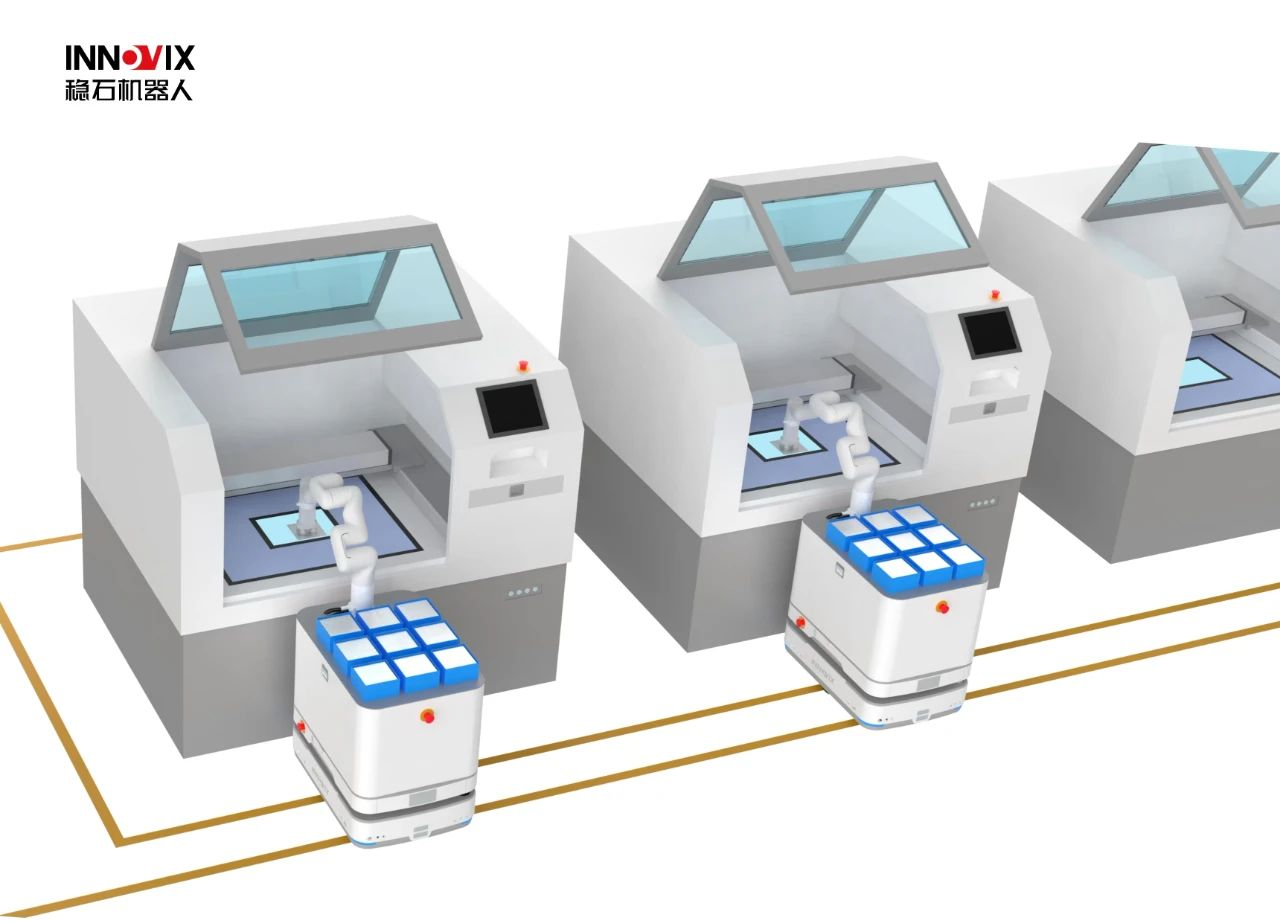

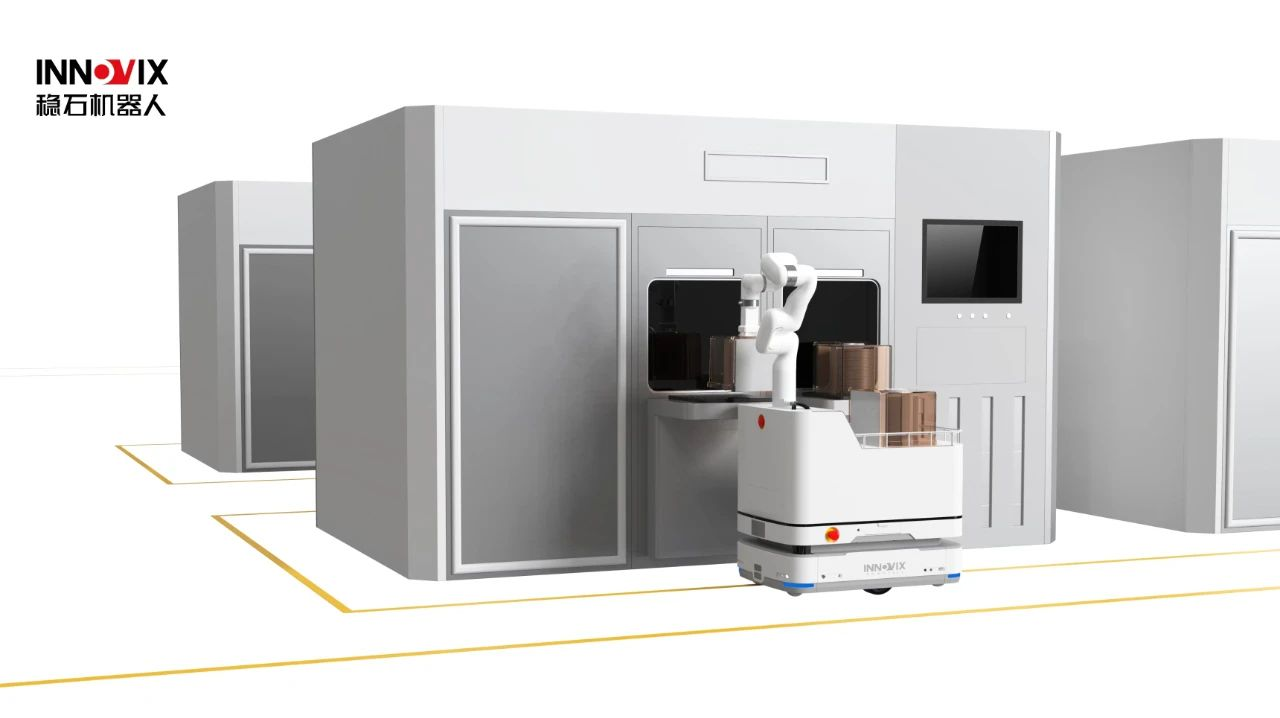

As a global leader in next-generation intelligent manufacturing robots, Innovix has independently developed the new-generation CS10 hybrid robot. With its exceptional performance and extensive application scenarios, it has become a key driver of industrial automation and smart manufacturing. The CS10 seamlessly integrates AMR, flexible collaborative robotics, and 3D vision technologies. Thanks to its remarkable precision and flexibility, it has been widely applied in industrial assembly, processing, inspection, loading, and unloading scenarios.

Innovation and Iteration, Highlighting Advantages:

More Precise

Innovix’s CS10 hybrid robot is equipped with a high-precision laser SLAM vision recognition system, achieving an operational accuracy of ±0.1mm. Leveraging deep learning and image recognition technologies, the robot can accurately locate target objects in complex environments and adjust its grasping strategy based on visual data, ensuring precision and stability in its operations.

More Efficient

The CS10 hybrid robot features Innovix’s independently developed next-generation scheduling system, Artistellar 1.0, which is the first edge-computing-based robot cluster scheduling system in China. By utilizing edge computing, it can process large amounts of data in real time, enabling precise path planning and task allocation. This system supports parallel multi-task processing, efficiently managing multiple robots on the production line and ensuring overall system coordination and efficiency.

Safer

The CS10 is Asia’s first hybrid robot product to be certified by Germany's TÜV Rheinland and the EU CE. It features multiple safety protection mechanisms and redundant designs, equipped with 360° radar for comprehensive monitoring. It can instantly detect high, medium, and low space obstacles, with automatic collision alerts and four-direction emergency stop protection. These features ensure high stability and low failure rates during long-term operation.

More Flexible

The CS10adopts a modular design, allowing it to be equipped with various end-effectors such as a 6-axis collaborative robotic arm, assembly fixtures, suction cups, and more. Its flexible design enables easy switching between different configurations.

More Adaptable

The CS10 features powerful adaptive learning capabilities. Its 3D vision system and laser SLAM navigation enable the construction of self-adaptive environmental maps without the need for modification. The machine learning algorithm continuously optimizes operational strategies, improving grasping accuracy and work efficiency. This allows the robot to handle dynamic production environments and diverse operational requirements.

The CS10 is widely used across multiple industries, with significant advantages in the following fields:

Electronics Manufacturing Industry

In the assembly and inspection of electronic components, the CS10 efficiently handles component transport, precise assembly, and quality inspection, significantly improving the automation level of the production line, shortening production cycles, and reducing manual intervention.

Automobile Industry

The CS10 plays a key role in the handling and assembly of automotive parts. It can quickly and accurately grab and position components, while supporting automated production processes, thereby enhancing production efficiency and reducing manufacturing costs.

Food Packaging Industry

In the food processing and packaging industry, the CS10can flexibly adapt to various packaging requirements, automatically performing tasks such as sorting, packaging, and stocking. Its efficient operations not only reduce labor costs but also ensure food safety and maintain production hygiene.

Warehouse Logistic Industry

The CS10 can perform automated material handling, picking, and sorting tasks in warehouses, effectively improving space utilization and logistics efficiency. By collaborating with devices such as AGVs and AMRs, Wensh robots can efficiently complete logistics transportation tasks, enabling intelligent warehouse management.

Innovix’s CS10 hybrid robot, with its advanced vision recognition, intelligent control, adaptive learning technologies, and flexible modular end-effector configurations, provides an efficient, flexible, and precise automation solution. Whether in electronics manufacturing, automotive industry, food packaging, or warehouse logistics, Wensh robots significantly enhance production efficiency, reduce operational costs, and assist enterprises in achieving digital and intelligent transformation. With continuous technological advancements, Wensh robots will continue to lead the development of industrial automation, bringing more innovation and transformation to global manufacturing