Introduction

By implementing thoughtful system planning, robot design, path planning, object identification, positioning, operation control, data interaction management, and integrating safety and monitoring measures, robots can autonomously navigate designated shelves and deliver goods to individuals.

Characteristics

Increase storage space

Realize single-depth and multi-depth storage in dense warehouses, and provide the maximum storage solution according to the different sizes and complexity of goods.

Strong environmental adaptability

The system can be deployed in various storage environments such as room temperature, cold storage, and constant temperature and humidity, especially suitable for industries with high environmental requirements such as pharmaceuticals and food.

Low labor cost

Reduce human operational risks

Improving homework efficiency

Accurate pick-up scheduling based on WMS system, 24-hour operation

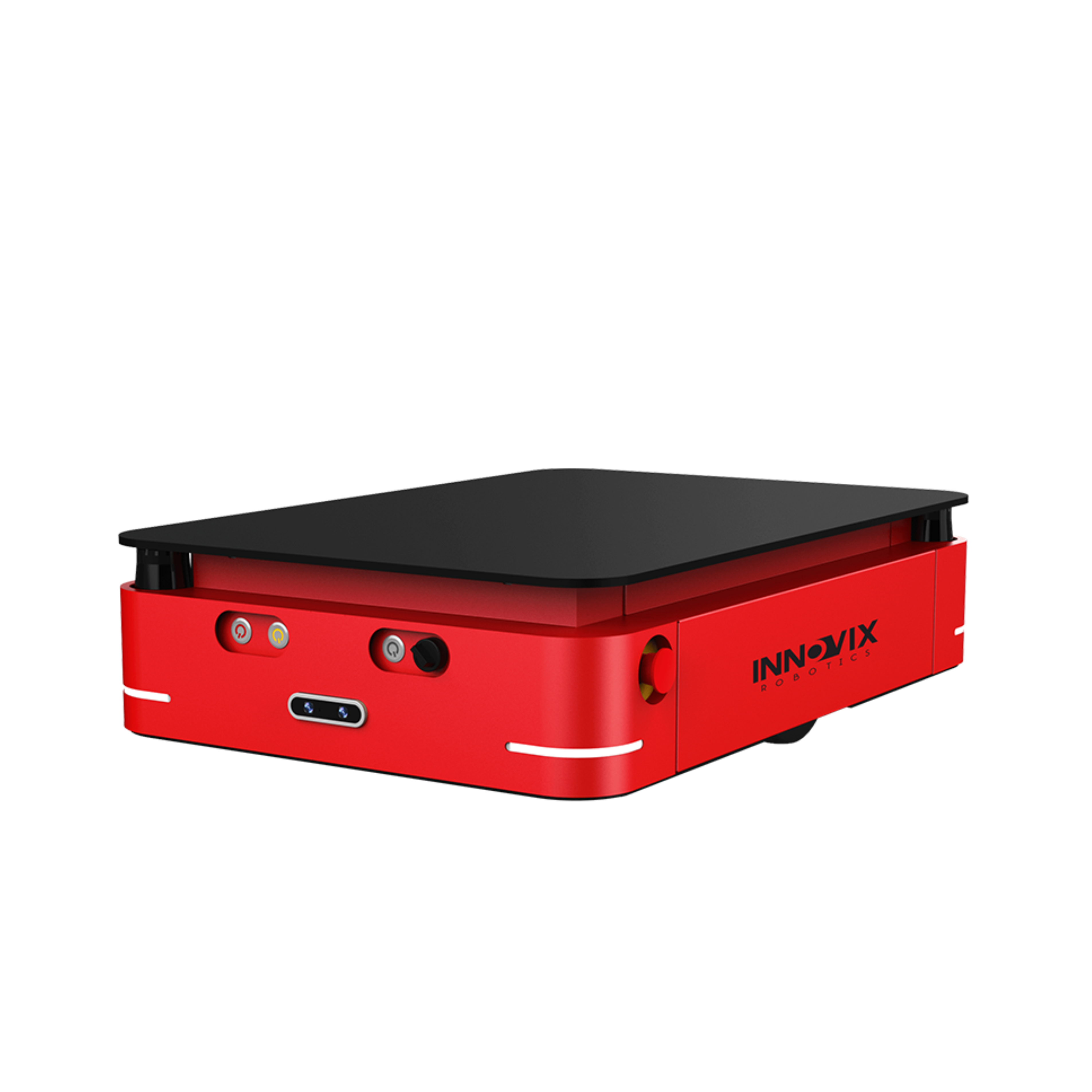

Solution Adaptation product

| Model |

Q600L |

S300 |

|

Size (L * W * H)

|

940mm*650mm*250mm | 820×580×316mm |

|

Weight

|

130Kg | 135kg |

|

Payload

|

600Kg

|

300kg |

|

Rotation Diameter

|

995mm

|

/ |

|

Lifting Stroke

|

60mm

|

/ |

|

Running Speed

|

0~2m/s

|

0-1.5m/s |

|

Stop Angle Accuracy

|

≤±1°

|

/ |

|

Stop Position Accuracy

|

≤±10mm

|

/ |

|

Maximum Passing Gap

|

≤10mm

|

/ |

|

Way of Communication

|

WiFi 2.4 GHz 802.11 g/n/ax,5 GHz 802.11 a/n/ac/ax

|

WiFi 2.4 GHz 802.11 g/n/ax,5 GHz 802.11 a/n/ac/ax |

|

Navigation

|

QR code + inertial navigation (slam optional)

|

/ |

|

Battery Capacity

|

DC48V/28AH

|

/ |

|

Charging Method

|

Automatic/manual charging

|

/ |

|

Minimum Ground Clearance

|

/

|

25mm |

|

Positioning Accuracy

|

/

|

≤±10mm |

|

One-way Minimum Aisle Width

|

/

|

900mm |

|

Two-way Minimum Aisle Width

|

/

|

1550mm |

|

Navigation

|

/

|

Laser + vision fusion navigation |

|

Drive Mode

|

/

|

Two wheel differential |

|

Passable Gap Width

|

/

|

≤30mm |

|

Certifications

|

/ | Optional CE; meets EN ISO 3691-4:2023, EN 1175:2020, EN 60204-1:2018 |